3D Printing Service

Custom Online 3D Printing Service

At Avinya Works, we provide end-to-end solutions including 3D printing services, product designing, and manufacturing to bring your ideas to life with speed, precision, and unmatched quality. Using advanced technologies like SLS (Selective Laser Sintering), SLA (Stereolithography), FDM (Fused Deposition Modeling), and DMLS (Direct Metal Laser Sintering), we deliver parts that meet the highest industry standards. Our expertise spans plastics (ABS, PLA, Nylon, PETG), resins, metals (aluminum, stainless steel, titanium), and ceramics—ensuring the right material for every project, from prototypes to functional end-use components. With fast turnaround times, strict quality checks, and versatile solutions, we serve industries like automotive, aerospace, medical devices, tooling, and consumer products, helping you accelerate innovation with confidence.

👉 Share your project details in the form below, and our experts will get back to you with the best solution and timeline tailored to your needs.

Avinyaworks Online 3D Printing Services: High-Quality Rapid Prototyping and Production Parts

Avinyaworks offers an industry-leading 3D printing service online. Whether you need prototypes or production parts, we can make them on demand. We are your one-stop shop for accurate, precise, custom 3D-printed parts at an affordable price. We use the latest additive manufacturing technology to build affordable, functional parts in over 60 metals and plastics. Avinyaworks offers eight high-quality 3D printing processes, including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, PolyJet, Carbon DLS, Nexa3D LSPc, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more. For a great introduction to additive manufacturing.

Thermoplastic 3D Printing

Selective Laser Sintering (SLS) 3D Printing Service

Selective Laser Sintering (SLS) 3D Printing Service is a widely used manufacturing solution for producing durable, high-quality parts from powdered materials. This technique is particularly suitable for functional prototypes, complex geometries, and small-batch production runs.

HP Multi Jet Fusion (MJF) 3D Printing Service

HP Multi Jet Fusion (MJF) 3D Printing Service offers a cutting-edge solution for producing high-quality, functional parts with exceptional detail and consistency. Leveraging HP’s advanced technology, MJF is ideal for both prototyping and full-scale production, providing speed, scalability, and superior material properties.

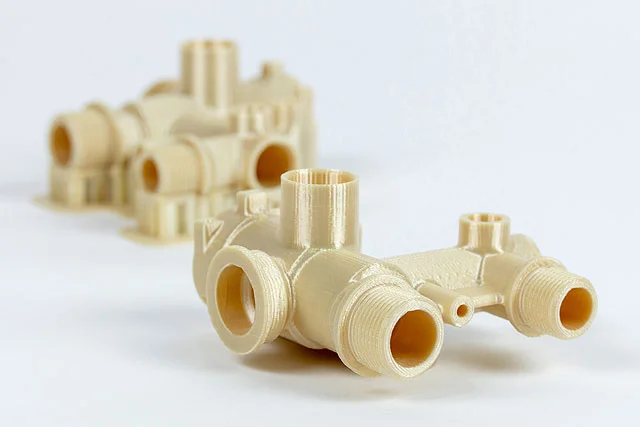

Fused Deposition Modeling (FDM) 3D Printing Service

Fused Deposition Modeling (FDM) 3D Printing Service provides a cost-effective and reliable solution for producing functional prototypes, low-volume production parts, and custom components. As one of the most widely used 3D printing technologies, FDM is ideal for both rapid prototyping and manufacturing durable end-use parts.

Thermoset 3D Printing

PolyJet 3D Printing Service

PolyJet 3D Printing Service delivers high-resolution, multi-material, and multi-color parts with exceptional surface quality and precision. This advanced additive manufacturing technology is ideal for realistic prototypes, detailed models, and complex designs, making it a top choice for industries requiring visual accuracy and functional performance.

Stereolithography (SLA) 3D Printing Service

Stereolithography (SLA) is a resin-based additive manufacturing process that uses a UV laser to cure liquid photopolymer resin layer by layer. The laser selectively solidifies the resin to form detailed parts with extremely smooth surface finishes and high accuracy, making it perfect for applications requiring precision and visual quality.

Metal 3D Printing

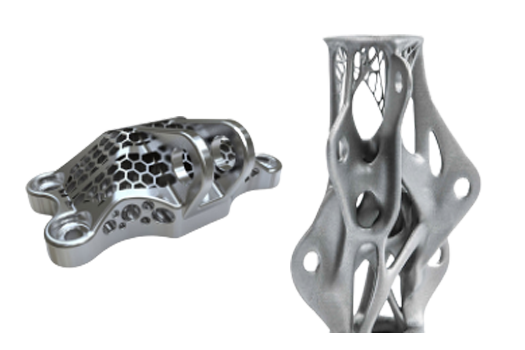

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Direct Metal Laser Sintering (DMLS) is an additive manufacturing process that uses a high-powered laser to selectively fuse metal powder layer by layer to create fully dense metal parts. DMLS is capable of producing intricate designs and complex internal structures that are challenging or impossible with traditional manufacturing methods like CNC machining.

Metal Binder Jetting 3D Printing Service

Metal Binder Jetting is an additive manufacturing process that uses a liquid binder to selectively bond layers of fine metal powder. After printing, the green part is subjected to a debinding and sintering process in a furnace to achieve full density and strength. Unlike laser-based metal 3D printing (like DMLS), Metal Binder Jetting does not require high-energy lasers, making it more efficient for larger production runs.

The Best 3D Printing Material Selection

Durable Nylon

Durable Nylon is a versatile, strong, and impact-resistant material widely used in 3D printing and manufacturing for both functional prototypes and end-use parts. Its excellent mechanical properties, including flexibility, durability, and chemical resistance, make it ideal for applications requiring high-performance components that withstand wear and stress.

ABS and ASA

ABS (Acrylonitrile Butadiene Styrene) and ASA (Acrylonitrile Styrene Acrylate) are two widely used thermoplastics in 3D printing and manufacturing, known for their durability, strength, and versatility. Both materials are excellent choices for functional prototypes, end-use parts, and outdoor applications, offering slightly different advantages based on environmental requirements.

ULTEM 9085 and ULTEM 1010

ULTEM™ 9085 and ULTEM™ 1010 are high-performance thermoplastics widely used in 3D printing and industrial applications. Known for their exceptional strength, heat resistance, and chemical stability, these materials are ideal for demanding industries such as aerospace, automotive, medical, and manufacturing.

Elastomers and Rubber-like Materials

Elastomers and Rubber-like Materials are a group of flexible, durable materials used in 3D printing to produce parts that need to exhibit elasticity, flexibility, and impact resistance. These materials are ideal for applications that require softness, stretchability, and the ability to return to their original shape after deformation.

Metal 3D Prints

Metal 3D Printing has revolutionized the manufacturing world, enabling the production of high-performance metal parts with complex geometries that would be difficult or impossible to create using traditional methods like machining or casting. With metal 3D printing, businesses can produce custom, lightweight, and durable metal components for a wide range of industries, from aerospace to automotive and medical devices.

Multi-Material & Full-Color Parts

Multi-Material & Full-Color 3D Printing is an advanced capability that allows for the creation of parts with multiple materials and colors in a single print. This technology enables the production of highly functional, visually complex, and intricate prototypes and end-use parts that are suitable for various industries, including product design, automotive, consumer goods, medical devices, and more.

Flame Retardant Plastic 3D Printing

Flame Retardant Plastic 3D Printing involves the use of specialized materials that are designed to resist or slow down the spread of fire, making them ideal for applications where safety and fire resistance are critical. These materials are often used in industries such as electronics, aerospace, automotive, and construction, where parts must meet stringent safety standards for fire resistance.

Applications of 3D Printing

Advantages of 3D Printing

Rapid Turnaround

Rapid Turnaround refers to the ability to complete a project, task, or production process in a very short amount of time, often in response to urgent demands or tight deadlines. In the context of 3D printing and manufacturing, rapid turnaround is a critical factor that enhances efficiency, reduces lead times, and allows businesses to react quickly to market needs or customer requests.

High-Quality, Organic Traffic

Durability in 3D printing refers to the ability of a printed object or part to withstand wear, pressure, stress, and environmental conditions over time without failing or degrading. In the context of 3D printing, ensuring that parts or products are durable is essential, especially when they will be used in demanding applications like automotive, aerospace, medical, or industrial environments.

Complex Geometry

Complex Geometry refers to the intricate, detailed, and often non-linear shapes that can be designed and manufactured using advanced techniques like 3D printing. These geometries are typically difficult or impossible to produce using traditional manufacturing methods like injection molding, casting, or machining, due to the constraints of tooling, material flow, and other limitations. In 3D printing, however, complex geometries can be easily achieved because the process builds objects layer by layer, allowing for greater design freedom and precision.

Precision

Precision in 3D printing refers to the accuracy with which a 3D printer can produce a part, specifically in terms of the dimensions, details, and tolerances of the printed object. It is one of the most critical factors for achieving high-quality prints, particularly in applications that require tight tolerances, fine details, and perfect fit.

Part Production

Part Production in 3D printing refers to the creation of end-use parts and components through additive manufacturing (AM) processes. Unlike traditional manufacturing methods, which rely on subtractive processes like machining or molding, 3D printing builds parts layer by layer, allowing for the production of complex shapes and structures with minimal waste. Part production using 3D printing is widely used across industries like aerospace, automotive, healthcare, consumer goods, and more due to its ability to create highly customized and intricate components quickly and efficiently.

Scalability

Part production using 3D printing is revolutionizing manufacturing processes across a wide range of industries. The technology offers unmatched flexibility, the ability to produce complex geometries, and the potential for rapid customization. While challenges such as material limitations and post-processing time remain, 3D printing continues to provide significant advantages, particularly for low-volume production, customization, and rapid prototyping. As technology advances, it is expected that 3D printing will play an even larger role in the future of manufacturing, enabling more efficient and innovative production solutions.

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

|

Part Size |

Avinyaworks can accommodate 3D printing up to 24″ x 36″ x 36″ without the need to split and bond parts. |

|

Minimum Feature Size |

0.030″ – 0.060″ is typical. |

|

Minimum Wall Thickness |

0.020″ – 0.060″ is typical. |

|

Clearance Between Features |

At least 0.030″ |

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital file. In this process, material is deposited layer by layer to build the final object. Unlike traditional manufacturing methods such as subtractive manufacturing (where material is removed from a solid block) or molding (where material is poured into a mold), 3D printing adds material incrementally, allowing for the creation of highly complex and customized shapes.

Why Choose Avinyaworks for 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our quality check includes visual inspection, dimensional verification, functionality testing (if applicable), and a review of surface finish.