HP Multi Jet Fusion (MJF) 3D Printing Service

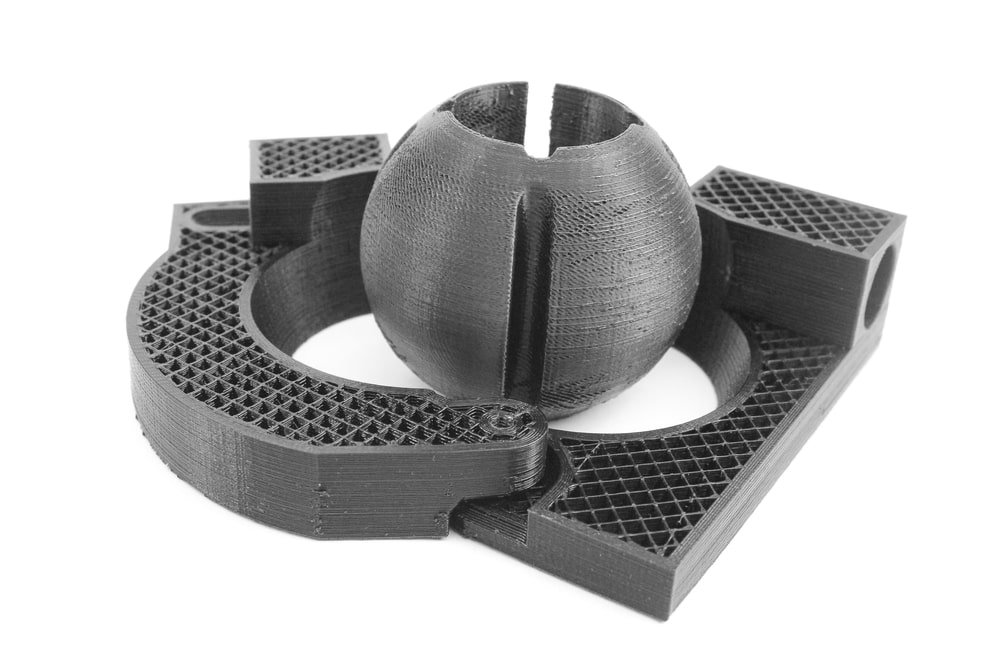

HP Multi Jet Fusion (MJF) is a cutting-edge 3D printing technology that uses inkjet-based printing to produce high-quality, functional parts with complex geometries. Unlike traditional 3D printing methods, MJF enables high-speed manufacturing of parts using powder bed fusion, where a powder material is selectively fused using heat and a binding agent. This technology is known for its precision, speed, and material versatility, making it ideal for industries that require functional parts, prototypes, and end-use products.

HP MJF 3D Printing Service

HP Multi Jet Fusion (MJF) is an advanced 3D printing technology that combines speed, precision, and material versatility to create high-quality functional parts. Whether used for rapid prototyping, customized products, or low-to-medium volume production, MJF offers significant advantages in terms of production speed, material properties, and part complexity. It is particularly valuable for industries such as aerospace, automotive, healthcare, and consumer goods where high performance, accuracy, and customization are required.

MJF Printing Materials

HP MJF Materials Available at Avinyaworks:

| Material Name | Description | Shore Hardness | Elongation at Break (XY, ZX %) | Impact Strength (XY, ZX kJ/m²) |

|---|---|---|---|---|

Nylon 11 | HP 3D High Reusability PA 11 | 80D | 55%, 40% | 6 kJ/m², 5 kJ/m² |

Nylon 12 | HP 3D High Reusability PA 12 | 80D | 20%, 15% | 3.6 kJ/m², 3.5 kJ/m² |

Nylon 12, Glass-Filled | HP 3D High Reusability | 82D | 10% | 3 kJ/m² |

Polypropylene (PP) | HP 3D High Reusability PP | 70D (est.) | 20% | 3.5 kJ/m², 3.0 kJ/m² |

TPU 88A | BASF Ultrasint™ TPU01 | 88A | 220%, 120% | Partial break, No break |

Applications for HP MJF

Vapor Smoothing HP Multi Jet Parts

Vapor smoothing is a post-processing technique used to enhance the surface finish of parts created with HP Multi Jet Fusion (MJF). This process helps achieve a smoother, more polished appearance by using chemical vapors to interact with the surface of the printed parts. The vapor dissolves the outermost layer of the material, resulting in a glossy finish and reducing the appearance of layer lines.

Advantages of HP Multi Jet Fusion

- Speed: Faster production times, especially for medium-to-large volumes.

- High-Quality Parts: Excellent mechanical properties, surface finish, and resolution.

- Customization: Highly suitable for creating custom, one-off, or small batch parts.

- Material Variety: A diverse range of materials with different performance characteristics.

- No Supports: The use of powder as support material eliminates the need for post-print support removal.

HP MJF Prototyping Tolerances

MJF Prototype Tolerances Based on HP 5200-Series, Balanced Mode

| Material Type | Under 30 mm (1.2″) | 30 – 50 mm (1.2″ – 2.0″) | 50 – 80 mm (2.0″ – 3.2″) | > 80 mm (3.2″) |

|---|---|---|---|---|

|

Rigid Materials (Nylon, PP)

|

± 0.70 mm (.028″) |

± 0.85 mm (.033″) |

± 1.40 mm (.055″) |

± 1.75 % |

|

Rubber-Like (TPU) |

± 1.05 mm (.041″) |

± 1.35 mm (.053″) |

± 1.80 mm (.071″) |

± 2.25 % |

HP MJF Engineer Reviewed & Production Tolerances

Engineered & Production MJF Tolerances Based on HP 5200-Series, Balanced Mode

| Material Type | Under 30 mm (1.2″) | 30 – 50 mm (1.2″ – 2.0″) | 50 – 80 mm (2.0″ – 3.2″) | > 80 mm (3.2″) |

|---|---|---|---|---|

|

Rigid Materials (Nylon, PP) |

XY = ± 0.25 mm (.010″) Z = ± 0.42 mm (.017″) |

XY = ± 0.30 mm (.012″) Z = ± 0.50 mm (.020″) |

XY = ± 0.39 mm (.015″) Z = ± 0.60 mm (.024″) |

XY = ± 0.5 % Z = ± 0.75 % |

|

Rubber-Like (TPU) |

XY = ± 0.60 mm (.024″) Z = ± 1.05 mm (.041″) |

XY = ± 0.60 mm (.024″) Z = ± 1.35 mm (.053″) |

XY = ± 0.60 mm (.024″) Z = ± 1.80 mm (.071″) |

XY = ± 0.75 % Z = ± 2.25 % |

HP MJF Feature and Build Size

| Description | Tolerance Notes |

|---|---|

|

Manufacturing Standards |

See all of our HP MJF manufacturing standards. |

|

Build Area |

Build area up to 15 x 11 x 15″ (14 x 11 x 13″ is the recommended usable area). |

|

Minimum Feature Size |

0.020″ (0.040″ recommended) or greater. |

|

Layer Thickness |

80 Microns (0.0031″) |

Overview: What is HP Multi Jet Fusion?

HP Multi Jet Fusion (MJF) is an advanced 3D printing technology that utilizes inkjet printing combined with thermal energy to produce highly accurate, functional, and durable parts. Unlike traditional additive manufacturing methods like Fused Deposition Modeling (FDM) or Stereolithography (SLA), MJF uses a powder bed fusion process to selectively fuse powdered materials, primarily polymers, to create complex geometries and end-use parts.

Developed by HP (Hewlett-Packard), MJF is recognized for its speed, precision, and versatility, making it ideal for industries requiring rapid prototyping, low-to-medium volume production, and functional components.

Key Benefits of HP Multi Jet Fusion

- MJF produces parts faster than traditional 3D printing methods. The ability to print full layers in one pass enhances throughput, making it ideal for high-volume production and rapid prototyping.

- MJF offers high accuracy and the ability to print fine details, making it suitable for parts requiring tight tolerances and complex geometries.

- Unlike other 3D printing methods that focus mostly on prototypes, MJF produces durable, functional parts with excellent mechanical properties, including strength, flexibility, and heat resistance.

- MJF supports a wide range of materials, mainly nylon-based powders, such as PA12, PA11, and PA12+. It also supports reinforced materials (e.g., glass-filled nylon) and high-performance polymers for demanding applications.

Why Choose Avinyaworks for HP MJF?

Endless Options

Choose from a vast array of combinations, including materials, finishes, tolerances, markings, and certifications, to customize your order.

Easy to Use

Receive your parts directly at your doorstep, eliminating the hassle of sourcing, project management, logistics, and shipping.

High Quality

Our quality check includes visual inspection, dimensional verification, functionality testing (if applicable), and a review of surface finish.