Selective Laser Sintering (SLS) 3D Printing Service

Selective Laser Sintering (SLS) is a popular 3D printing technology that uses a laser to sinter (fuse) powdered material into a solid structure based on a 3D model. It is particularly useful for creating strong, durable parts with intricate geometries, often used in industries such as aerospace, automotive, and medical devices.

What is SLS 3D Printing?

Selective Laser Sintering (SLS) 3D printing is an advanced manufacturing process that uses a laser to fuse powdered materials into solid objects. It is a form of Additive Manufacturing where material is added layer by layer to create a final part, based on a 3D model. SLS is widely used for both prototyping and production of functional parts due to its precision, material strength, and versatility.

SLS Materials

Selective Laser Sintering 3D Printing Materials

| Material Name | Other Common Names | Shore Hardness | Elongation at Break (%) | Impact Strength, Notched (kJ/m²) |

|---|---|---|---|---|

|

Nylon 12 |

Durable plastic, PA12, PA 2200 |

75D |

18% |

4.8 kJ/m² |

|

Nylon 12, Glass-filled (GF) |

Stiff plastic, PA12 GF, PA 3200 GF |

80D |

9% |

4.2 kJ/m² |

|

Nylon 11 EX |

Ductile plastic, PA11, Rilsan® Invent Natural |

77D |

45% |

No break |

|

Nylon 12, Carbon-Filled (CF) |

High-performance plastic, carbon-filled PA12, PA 602-CF, carbonmide |

N/A |

4% |

5.3 kJ/m² |

|

Nylon 12, Aluminum-Filled (AF) |

Metallic gray plastic, aluminum-filled PA12, alumide |

76D |

3% |

4.6 kJ/m² |

|

Nylon 12, Mineral-Filled (HST) |

Heat-resistant plastic, mineral fiber-reinforced PA12, PA 620-MF |

75D |

3-5% |

N/A |

|

Nylon 12, Flame Retardant (FR) |

Meets the FAR 25.853 60 second burn specification, PA 606-FR |

73D |

24% |

N/A |

SLS Finishes

Standard

SLS parts are de-powdered using a combination of sandblasting and manual powder removal techniques. Any internal holes that are accessible may be drilled to the desired size. The surface finish of the parts is typically a white matte texture, resembling a fine sugar-cube appearance.

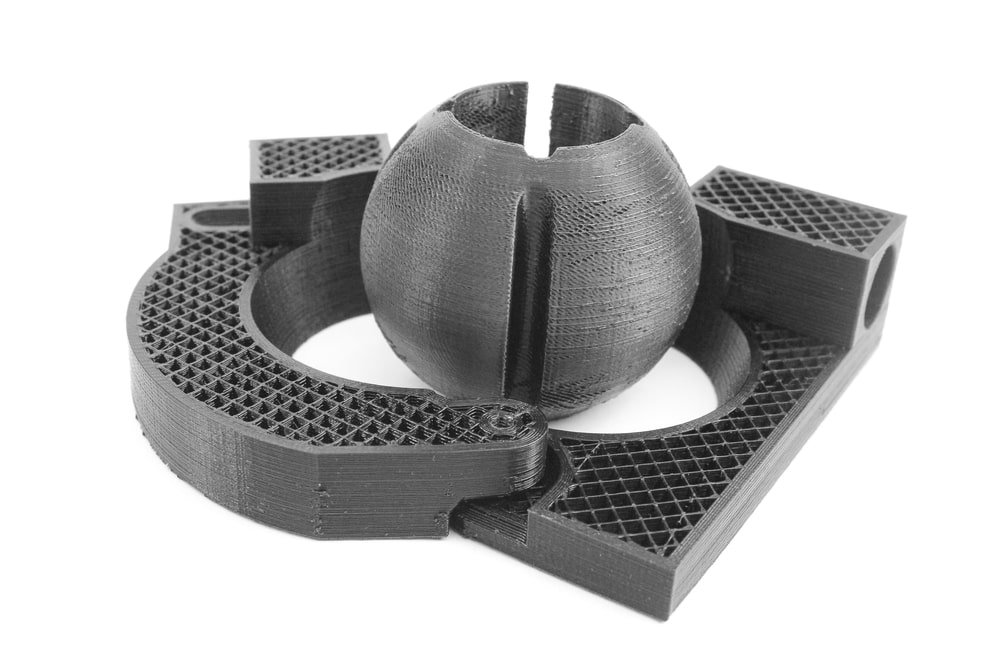

Color Dyed

Color options for SLS parts include black, blue, green, red, or yellow. Batch-to-batch consistency may vary slightly, with black being the most consistent. The dye penetrates approximately 0.010″ into the surface of the part.

Vapor Smoothing

An automated post-processing technology, AMT PostPro3D, is used to achieve a high-quality surface finish. Vapor smoothing enhances most surfaces, transforming them from matte to a semi-gloss finish. In addition to improving aesthetics, vapor smoothing seals the surface, enhances mechanical properties, and ensures a consistent cosmetic finish suitable for production. Vapor-smoothed parts can also be dyed for further customization.

Media Tumbled

The standard finish is enhanced with abrasive media tumbling. This process reduces visible growth lines and softens sharp edges, resulting in a smoother surface. The parts are left with an eggshell finish, providing a refined, matte appearance.

Nickel Plating

The standard finish is complemented by a secondary copper and nickel plating process, adding a 0.004″-0.006″ nickel coating. This nickel plating enhances the part’s durability, stiffness, and wear resistance, though it is not considered cosmetic. The final finish is a rough nickel texture.

Vapor Smoothing SLS 3D Printed Parts

Vapor Smoothing for SLS 3D Printed Parts is a post-processing technique used to improve the surface finish and mechanical properties of parts produced through Selective Laser Sintering (SLS). This process involves using a vaporized solvent to smooth the surface of the printed parts, enhancing both their appearance and performance.

Applications for Selective Laser Sintering

Vapor Smoothing HP Multi Jet Parts

Vapor smoothing is a post-processing technique used to enhance the surface finish of parts created with HP Multi Jet Fusion (MJF). This process helps achieve a smoother, more polished appearance by using chemical vapors to interact with the surface of the printed parts. The vapor dissolves the outermost layer of the material, resulting in a glossy finish and reducing the appearance of layer lines.

Advantages of SLS

Complex Geometries

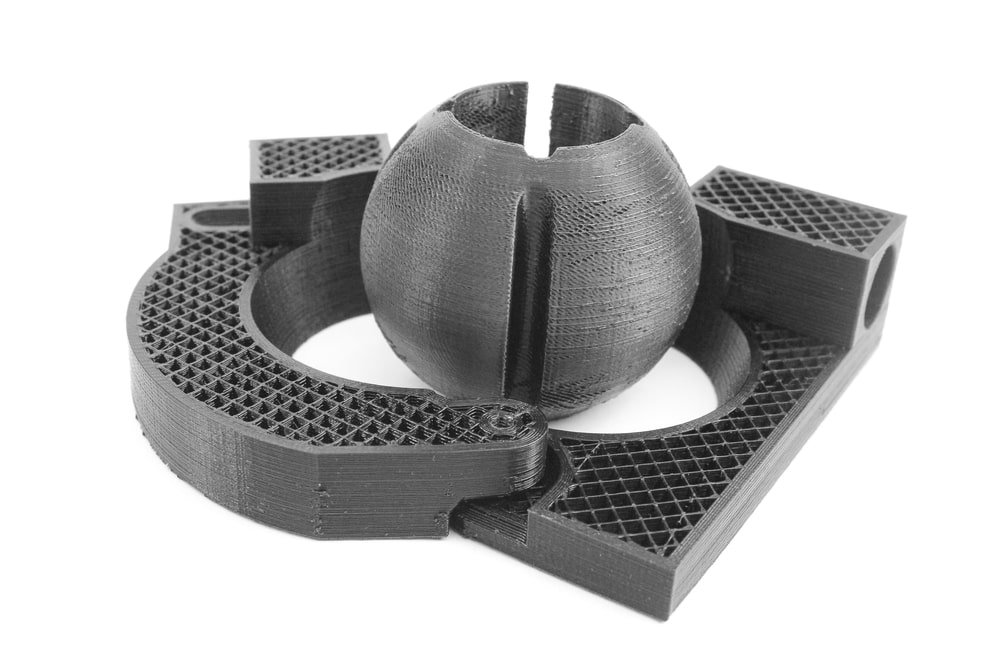

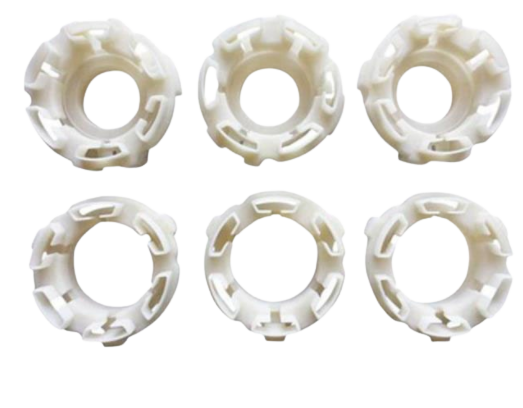

- SLS allows for the creation of highly complex geometries, including internal structures, overhangs, and intricate designs that would be difficult or impossible with traditional manufacturing methods.

- It can produce parts with internal cavities, lattice structures, and complex shapes without the need for support structures.

No Need for Support Structures

- The surrounding powder acts as support during the printing process, eliminating the need for additional support structures, which simplifies post-processing and reduces material waste.

- This also allows for more design freedom and faster production times.

Strong, Durable Parts

- SLS produces parts with excellent mechanical properties, including strength, stiffness, and durability. It’s ideal for functional prototypes and end-use parts.

- Materials like Nylon (PA12), Glass-filled Nylon, and TPU provide strength and flexibility, making the parts suitable for real-world applications.

Material Variety

- SLS supports a wide range of materials, including plastics, metals, and composite materials. These include Nylon, Alumide (nylon with aluminum), TPU (rubber-like material), and even metals in some advanced SLS systems.

- This versatility allows for customized material selection based on specific requirements like flexibility, heat resistance, or chemical durability.

High Accuracy and Detail

SLS offers high precision, which is ideal for applications that require detailed, intricate parts. The laser sintering process ensures consistent and accurate layer alignment, resulting in high-quality finishes and dimensional accuracy.

Rapid Prototyping

- SLS enables quick turnaround times for prototypes, allowing for faster iterations and design changes. This is particularly beneficial for industries like aerospace, automotive, and consumer goods, where prototyping speed is critical.

- It also reduces the need for expensive tooling and molds, making it ideal for low-volume or one-off production.

Scalability

SLS technology is highly scalable, meaning it can be used for both prototyping and full-scale production. As demand grows, production can be ramped up without significant changes to the process or tooling.

SLS General Tolerances

| Description | Tolerance Notes |

|---|---|

|

General Tolerances |

SLS Nylon 12 and variants are ± 0.015”, or ± 0.002″ per inch, whichever is greater.* SLS Nylon 11 and variants are ± 0.020”, or ± 0.003″ per inch, whichever is greater.* *Results are typical. |

|

Build Area |

Build area up to 13″ x 13″ x 20″. Glass filled can extend up to 26″ x 15″ x 23″. |

|

Minimum Feature Size |

0.030″ or greater. |

|

Standard Layer Thickness |

0.0045″ |

Overview: What is SLS?

Selective Laser Sintering (SLS) is a powder bed 3D printing technology that creates highly accurate and durable parts, suitable for end-use applications and low-volume production. Often considered a cousin to the popular Direct Metal Laser Sintering (DMLS) technology, SLS works by using a laser to precisely fuse layers of powder material based on a 3D CAD file. While both processes involve laser sintering to build parts from powdered materials, SLS primarily uses nylon or polyamide powder, making it ideal for functional prototypes and durable parts, whereas DMLS uses metal powders, typically for more specialized applications in metal parts. Both technologies are commonly used for prototyping and low-volume production, offering fast production times and flexibility in part design.

Benefits of SLS 3D Printing

- SLS allows for the creation of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This includes parts with internal cavities, lattice structures, or detailed geometries.

- The lack of need for support structures gives designers the freedom to create more advanced and customized parts without worrying about the limitations of traditional tooling.

- Unlike other 3D printing methods, SLS does not require support structures. The surrounding powder bed supports the part throughout the printing process, eliminating the need for additional material or post-processing to remove support structures.

- This reduces material waste and simplifies the overall manufacturing process.

- SLS offers high accuracy, enabling the production of parts with fine details, sharp features, and precise tolerances. This makes it suitable for both prototyping and low-volume production of parts that require tight specifications.

Why Choose Avinyaworks For SLS Printing Service?

Endless Options

Choose from a vast array of material options, finishes, tolerances, markings, and certifications to customize your order to meet your exact specifications.

Easy to Use

Receive your parts delivered directly to your door, eliminating the hassle of sourcing, project management, logistics, and shipping.

High Quality

Receive high-quality parts delivered directly to your door, eliminating the hassle of sourcing.