3D Scanning Service

Why 3D Scanning?

Our 3D Scanning Services offer precise and efficient solutions for capturing the geometry and details of physical objects, enabling accurate digital representations for a wide range of applications. Whether you’re looking to reverse engineer a part, create 3D models for analysis, or preserve a heritage object, our advanced 3D scanning technology delivers exceptional results.

The technique can be used for the following purposes:

- To archive or reproduce moulds, fixtures and tooling.

- To document and preserve hand-built designs.

- To reverse-engineer a part that has no drawings.

- For re-creating a part using new methods such as 3D printing.

- For inspection of parts for accurate manufacturing.

- For Obtaining models for FEA and CFD simulation.

- To capture its existing shape to analyze it for flaws or defects.

- To reduce the cost of manufacturing and time for designing.

What is 3D Scanning & How it Works?

Surface Preparation

The process begins with applying a temporary matte powder coating to the object to enhance scan accuracy. Glossy, reflective, or transparent surfaces can negatively impact scan quality, and the matte coating ensures that the scanner captures every detail precisely.

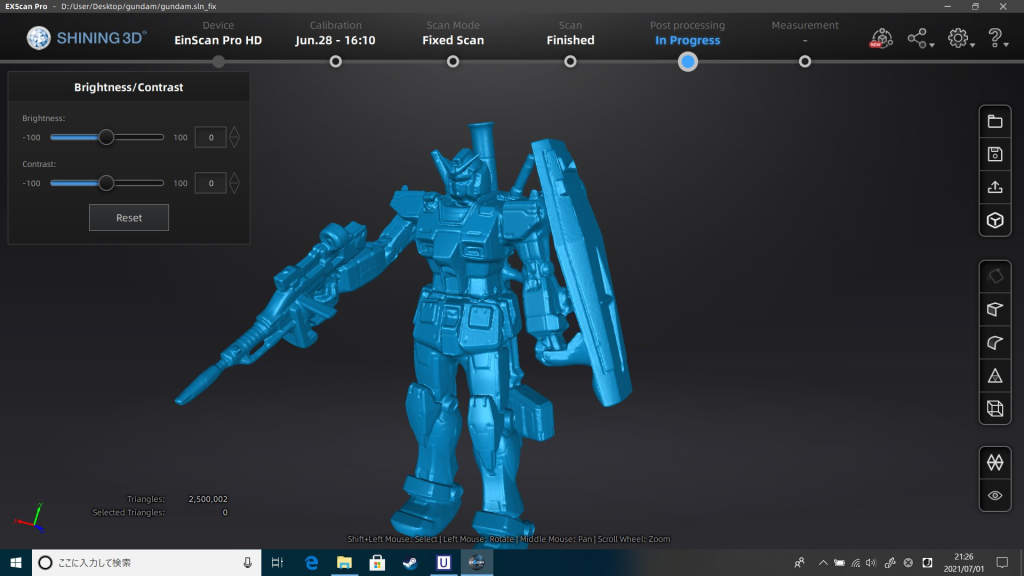

High-Precision 3D Scanning

After coating, we use advanced 3D scanning technology to capture key sections of the part from various angles. Our experts carefully scan each view, ensuring automatic alignment and creating a comprehensive 3D model.

Data Refinement

Once the scanning is complete, we process the data by filling in any gaps and simplifying the model. This step ensures that the data is manageable and ready for CAD integration, preserving essential details while optimizing the model for further use.

CAD Conversion and Reverse Engineering

The refined scan data is imported into CAD software, where it undergoes further trimming, alignment, fusion, and polishing. Our team uses advanced reverse engineering tools to ensure the model meets design specifications and is ready for modifications or production.

Final Design & 3D Printing

After the necessary revisions, the 3D model is polished to perfection and is now ready for prototyping or production. The finalized design can be used for 3D printing or further manufacturing processes.

What Does Our Service Include?

Scanning and Redesigning

A critical aspect of reverse engineering, we thoroughly scan your components using various advanced techniques, including CAM, CAD, 3D, and CAE. Our experts collaborate with you to identify areas for improvement and suggest minor design changes that can enhance the overall engineering process.

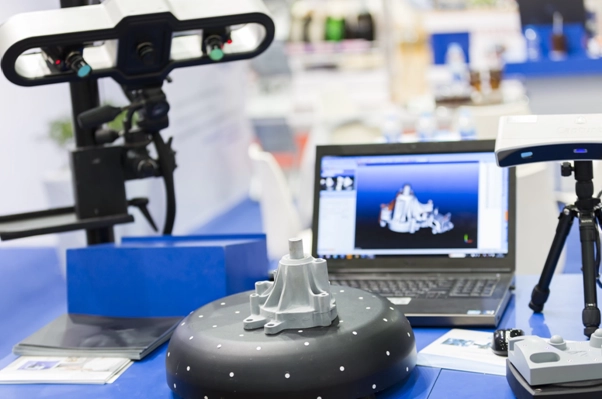

Onsite Scanning Services

We utilize a wide array of 3D scanners for onsite projects, including point cloud scanning and 3D digitization. Our scanners come with various accuracy ranges to fit specific needs:

- Laser Handheld 3D Scanners: Accuracy from 0.05 mm to 0.1 mm.

- White & Blue Light Scanners: High precision, with accuracy ranging from 0.01 mm to 0.03 mm.

- Laser 3D Scanners: Accuracy from 0.5 mm to 1 mm for larger scanning tasks.

Scanning and Prototyping

Our reverse engineering services include effective 3D scanning, enabling you to create prototypes at a significantly reduced cost. The data from scanning is used to accurately design and refine prototypes, streamlining the entire process.

Converting STL to STEP Formats for Reverse Engineering

We specialize in converting 3D scan data (STL) into CAD formats (STEP). The process of reverse engineering is not automatic, and it requires manual reconstruction of solid models from scans. With our expert team and advanced software, we provide precise and high-quality results, ensuring the best possible outcome for your project.

3D Scanning and reverse engineering

Avinyaworks provides expert component and assembly reverse engineering services. By leveraging our advanced optical scanners and cutting-edge reverse engineering software, our team is capable of accurately creating CAD models and technical drawings from any physical component provided. This ensures precise digital representations that facilitate design modifications, prototyping, and manufacturing processes.

What Does Our Service Include?

Applications of Reverse Engineering

Reverse engineering involves creating a digital twin from a physical component or assembly. This process has a wide range of applications across design, engineering, and manufacturing, including:

Recreating Manufacturing Data for Obsolete Parts: Reverse engineering is ideal for recreating data for parts that are no longer in production or for which original design files are unavailable.

Competitor Product Analysis: This process enables precise analysis of competitor products, helping to understand their design, performance, and potential areas for improvement.

Digital Archiving: Reverse engineering allows for the digital preservation of physical components, making it easier to store, retrieve, and manage designs for future use.

Simulations and Calculations: Once the digital model is created, it can be used for simulations, performance analysis, and calculations, enabling design optimization and validation.

Reverse Engineering Process

Initial 3D Scanning: Once your object is submitted, we perform a detailed 3D scan using our comprehensive 5-step scanning process to ensure the highest level of precision.

Data Processing and Refinement: The scanned data is carefully processed and refined to create an accurate and fully defined design.

3D Modeling and Manufacturing Drawings: Finally, we generate functional 3D models and detailed manufacturing drawings based on the final design, ready for production or further analysis.

Dedicated Scanners

Maintenance, Repair & Recreation Of OEM Parts

Maintenance

- Creating digital twins: Digital twins are virtual replicas of a physical object or system which can be used to monitor the performance of the physical object, simulate its behavior, and predict potential issues.

- Quality control: Using 3D scanning, you can perform quality control checks on parts to ensure they meet certain tolerances and dimensions. Many manufacturers use 3D scanning to accelerate their quality control processes since 3D scanners enable non-contact, highly precise 3D profile measurements.

- Reverse engineering: If the maintenance requires a part that is no longer available or has been discontinued, 3D scanning can be used to reverse engineer it and create a replacement.

Repair

- Identifying issues: You can scan damaged parts to detect the extent of the damage for planning the repairs accordingly.

- Creating replacement parts: If a certain part gets damaged beyond repair, 3D scanning can be used to create a replacement part, which you can fabricate using additive manufacturing techniques.

- Verifying repairs: Once you’re done with the repair process, you can use 3D scanning to verify that the part has been restored to its original specifications.

Recreating OEM Parts

- Scanning the original part: A 3D scan is taken of the original part, capturing its geometry and dimensions.

- Reverse engineering: The 3D scan is used to create a digital model of the part, which can be used to generate a CAD model.

- Additive manufacturing: The CAD model can be used to fabricate a replica of the original part using additive manufacturing techniques like 3D printing.

Scanner Specifications

Scan Mode | Handheld HD Scan | Handheld Rapid Scan | Fixed Scan with/without Turntable (with Add-on: Industrial Pack) |

Scan Accuracy | up to 0.045 mm | up to 0.1 mm | 0.04 mm (single shot accuracy) |

Volumetric Accuracy* | 0.3 mm/m (Markers Alignment) | 0.3 mm/m (Markers Alignment) | – |

Scan Speed | 10 frames/s; 3,000,000 points/s | 30 frames/s; 1,500,000 points/s | Single Scan<0.5s |

Point Distance | 0.2 mm-3 mm | 0.25 mm-3 mm | 0.24 mm |

Single Scan Range | 209*160 mm——310*240 mm | ||

Depth of Field | ±100 mm | ||

Working Distance | 510 mm | ||

Light Source | LED | ||

Texture Scan | Yes (with Add-on: Color Pack) | Yes (with Add-on: Color Pack) | Yes (with Add-on: Color Pack) |

Outdoor Operation | Set up the shelter or cover to avoid direct sunlight | ||

Special Scan Object | For the transparent, highly reflective or some dark objects, please spray powder before scanning | ||

Output Formats | OBJ; STL; ASC; PLY; P3 ; 3MF | ||

Operating Temperature Range | 0-40℃ | ||

Operating Humidity Range | 10-90% | ||

Why Choose Avinyaworks?

Avinyaworks is your one-stop solution for a wide range of services, including New Product Design & Development, 3D Scanning, Reverse Engineering, 3D Printing, Injection Molding, Vacuum Casting, and CNC Machining.

Our team of highly skilled and experienced engineers is dedicated to delivering high-quality products within the agreed timeline. We pride ourselves on offering these services at affordable prices, ensuring accessibility for everyone. Additionally, we provide special discounts on 3D scanning services.

If you’re ready to move forward with manufacturing your product, don’t hesitate to contact us today!