CNC Machining Service

CNC Machining Services

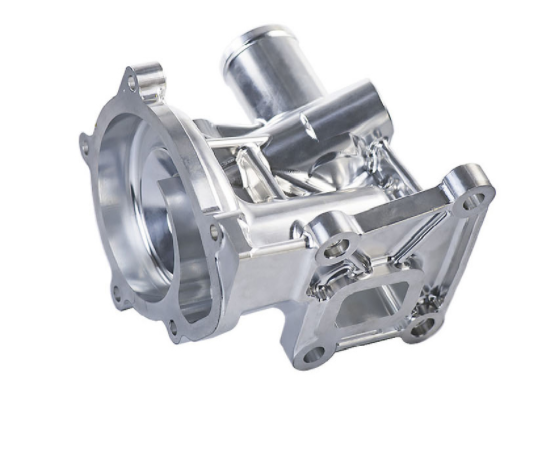

CNC Machining Services involve the use of Computer Numerical Control (CNC) machines to automate the precise cutting, shaping, drilling, and finishing of materials based on a digital design file. CNC machining is widely used in manufacturing industries for creating highly accurate, complex, and detailed parts. The process involves controlling the movement of machine tools using a computer, which allows for high precision, repeatability, and speed.

Why Use Avinyaworks for Custom Online CNC Machining Services?

CNC machining services are a versatile and reliable solution for producing high-precision, complex parts across a wide range of materials. Whether you’re creating a prototype, custom part, or high-volume production component, CNC machining offers accuracy, efficiency, and the ability to work with various materials, making it a key technology in modern manufacturing.

CNC Machining Services

Custom CNC Milling Services

Custom CNC Milling Services involve the use of Computer Numerical Control (CNC) machines to precisely machine custom parts and components from a variety of materials. CNC milling is ideal for producing complex shapes, intricate designs, and tight tolerances for a wide range of industries, including aerospace, automotive, medical, and consumer products.

CNC Turning Service

CNC Turning Service involves the use of Computer Numerical Control (CNC) machines to precisely machine cylindrical parts by removing material from a rotating workpiece. CNC turning is ideal for creating round or cylindrical components with high precision, and is commonly used in industries such as aerospace, automotive, medical devices, and electronics.

CNC Routing Services

CNC Routing Services involve the use of Computer Numerical Control (CNC) routers to automate the cutting, shaping, and engraving of materials like wood, plastics, and composites. CNC routers are similar to CNC milling machines but are typically used for larger parts or softer materials. This service is ideal for creating intricate shapes, patterns, and detailed designs in a variety of industries, including woodworking, signage, aerospace, and more.

3D Printing General Tolerances

| Feature | Description |

|---|---|

Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. |

Standard Lead Time | 3 business days |

General Tolerances | Tolerances on metals will be held to +/- 0.005″ (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

Precision Tolerances | Avinyaworks can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and GD&T callouts. |

Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

Threads and Tapped Holes | Avinyaworks can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

Edge Condition | Sharp edges are broken and deburred by default |

Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Metal CNC Machining Materials

CNC Machining Aluminum Alloys

- Aluminum 6061

- Aluminum 5052

- Aluminum 2024

- Aluminum 6063

- Aluminum 7050

- Aluminum 7075

- Aluminum MIC-6

CNC Machining Copper Alloys

- Copper 101

- Copper C110

CNC Machining Bronze Alloys

Copper C932

CNC Machining Brass Alloys

- Copper 260

- Copper 360

CNC Machining Stainless Steel Alloys

Nitronic 60 (218 SS)

- Stainless Steel 15-5

- Stainless Steel 17-4

- Stainless Steel 18-8

- Stainless Steel 303

- Stainless Steel 316/316L

- Stainless Steel 416

- Stainless Steel 410

- Stainless Steel 420

- Stainless Steel 440C

CNC Machining Steel Alloys

- Steel 1018

- Steel 1215

- Steel 4130

- Steel 4140

- Steel 4140PH

- Steel 4340

- A2 Tool Steel

- O1 Tool Steel

CNC Machining Titanium Alloys

- Titanium (Grade 2)

- Titanium (Grade 5)

CNC Machining Zinc Alloys

Zinc Alloy

Plastic CNC Machining Materials

ABS

High-strength engineering plastic used for many commercial products.

Acrylic

A clear glass-like plastic. Good wear and tear properties. Great for outdoor use.

Delrin (Acetal)

- Acetal

- Delrin 150

- Delrin 100

Garolite

- Garolite G10 (FR4)

- Garolite G10 (non-FR)

- Garolite G11 (FR5)

HDPE

High-density polyethylene is a moisture and chemical-resistant plastic with good impact strength. The material is outstanding for outdoor applications as well as watertight containers or seals.

Nylon 6/6

Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance.

PC (Polycarbonate)

With almost twice the tensile strength of ABS, polycarbonate has superior mechanical and structural properties. Used widely in automotive, aerospace, and other applications that require durability and stability.

CNC Machining Zinc Alloys

Zinc Alloy

PEEK

- PEEK

- PEEK (USP Class VI TECAPEEK)

- PEEK GF30

Polypropylene

Has excellent electrical properties and little or no moisture absorption. It carries light loads for a long period in widely varying temperatures. It can be machined into parts requiring chemical or corrosion resistance.

PTFE (Teflon)

This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator.

UHMW PE

Ultra-high molecular weight polyethylene. A general-purpose material. It offers a unique combination of wear and corrosion resistance, low surface friction, high impact strength, high chemical resistance, and does not absorb moisture.

PVC

Polyvinyl chloride (Type 1) is a highly chemical-resistant synthetic plastic, PVC is commonly in environments exposed to liquids or requires electrical insulation.

ULTEM

- ULTEM 1000

- ULTEM 2300

CNC Machining Finishes

Standard (As-Milled)

The finish option with the quickest turnaround is the as-machined finish, where CNC machined parts are left with visible tool marks and potentially sharp edges or burrs. These can be removed upon request. The surface finish is typically comparable to a 125 µin Ra finish, offering a functional surface that may require additional post-processing for smoother or more refined appearances.

Bead Blast

The part surface is left with a uniform, smooth, and matte appearance, providing a clean finish that reduces surface imperfections while maintaining a consistent texture.

Tumbled

The part surface is left with a consistent, smooth, and matte finish, reducing surface imperfections while ensuring a uniform texture.

Anodized (Type II or Type III)

- Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish, typically applied to aluminum. Parts can be anodized in various colors, with clear, black, red, and gold being the most common options.

- Type III (MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2 “hardcoat”) produces a thicker anodized layer, offering both enhanced wear resistance and the corrosion resistance of Type II. This type is ideal for applications requiring increased durability and strength. For examples of our anodized finishes, please refer to our metal finishes gallery.

Titanium Anodize

A surface finish for titanium according to the AMS-2488 Type 2 specification, also known as Tiodize. This finish enhances the fatigue strength and wear resistance of titanium parts. Titanium anodized parts are commonly used in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes result in a dull, matte shine.

PTFE Impregnated Hard Anodize

A hard coat anodizing process that incorporates PTFE (polytetrafluoroethylene) to create a self-lubricating, dry-contact surface with the protective properties of a Type 3 hard coat. This finish is suitable for aluminum alloys or titanium and enhances the service life of the product by reducing friction and wear. It conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed) specification.

Chem Film (Chromate Conversion Coating)

Chem Film provides excellent corrosion resistance and good conductivity properties, making it ideal for protecting metal surfaces. It can also serve as a base for paint adhesion. The finish often leaves the surface with a yellow or gold appearance. Chem Film adds minimal thickness, typically ranging from 0.00001″ to 0.00004″. This finish conforms to MIL-DTL-5541, TYPE I/II specifications.

Passivation

Passivation enhances the corrosion resistance of 200 and 300 series stainless steels, as well as precipitation-hardened corrosion-resistant steels. The process adds negligible thickness, typically around 0.0000001″. This finish conforms to industry standards, including ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, and AMS 2700.

Powder Coat

In the powder coating process, powdered paint is sprayed onto a part and then baked in an oven, creating a strong, wear-resistant, and corrosion-resistant finish. This method results in a more durable layer compared to standard painting techniques. A wide range of colors is available, allowing for both functional and aesthetic customization. For examples, please refer to our powder coating finishes gallery.

Electropolishing

Electropolishing is an electrochemical process that cleans steel parts, improving their appearance by making the metal brighter while also reducing corrosion. This process removes a thin layer of material, typically 0.0001″ to 0.0025″ from the surface. It conforms to ASTM B912-02 standards.

Electroless Nickel Plating

Electroless nickel plating provides a uniform nickel coating that offers enhanced protection against corrosion, oxidation, and wear, even on irregular surfaces. The process results in a brighter finish, and the thickness typically starts at 0.0001”. This finish conforms to MIL-C-26074 standards.

Silver Plating

Silver plating provides excellent solderability and electrical conductivity, making it ideal for applications requiring these properties. However, silver is susceptible to tarnishing over time. The plating conforms to AMS QQ-S-365D standards, with a typical thickness ranging from 0.00002″ to 0.0003″.

Gold Plating

Gold plating offers excellent corrosion and tarnish resistance, along with superior solderability. It is commonly used for electrical connections and other high-performance applications. The default application specifications are MIL-G-45204 and ASTM B488, CLASS 00, 0, or 1. The typical plating thickness ranges from 0.00002″ to 0.00005″.

Zinc Plating

Zinc plating provides a uniform coating that offers excellent protection against corrosion, oxidation, and wear, even on irregular surfaces. This finish is commonly used to enhance the durability of steel and iron parts. It conforms to ASTM B633-15 standards.

CNC Machining Design Guidelines

| Feature | Description |

|---|---|

|

Internal corner fillets |

Design internal corner fillets to be 0.020” – 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii. |

|

Floor fillets |

Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior. |

|

Undercuts |

Always design undercuts to standard sizes and away from corners so they are accessible by the cutting tool. |

|

Tapped/threaded hole depth |

Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads. |

|

Complexity |

Keep the number of small cuts to a minimum to reduce CNC machining costs; only design in the necessary features to balance function with aesthetic. |

Advantages of CNC Machining

Precision and Accuracy

CNC machines are highly precise and capable of producing parts with tight tolerances, often up to 0.001mm or better. The computer-controlled process ensures that each cut or movement is executed exactly as programmed, reducing human error and increasing consistency.

Repeatability

Once a CNC machine is programmed, it can produce identical parts consistently. This repeatability is crucial for mass production or when producing parts that require high consistency across many units.

Complex Geometry

CNC machines are capable of creating intricate and complex shapes that would be difficult or impossible with manual tools. Advanced capabilities like 5-axis CNC machining allow for complex designs and detailed features with high precision.

Speed and Efficiency

CNC machines can operate continuously without the need for breaks, making them faster than manual operations. They can also perform multiple tasks (drilling, milling, turning) in one set-up, reducing the time spent on setup and improving overall production speed.

Automation and Reduced Labor Costs

CNC machining is highly automated, reducing the need for manual labor. This not only decreases labor costs but also minimizes human error and variability in the production process.

Flexibility in Production Volume

CNC machining is suitable for both small batch and large-scale production. Small runs, custom parts, and prototypes can be produced quickly, while the machines can also be set up for mass production runs with minimal setup time.

Challenges of CNC Machining

One trade-off when leveraging the high performance of CNC machining processes is that increased geometric complexity comes with additional costs. Simple, bulky parts are ideal for CNC milling and turning, as they are easier to machine and require less time and effort. However, more intricate designs may be challenging due to tool access limitations. The extent of these limitations depends on the number of axes the machine uses—essentially, the more axes involved, the more complex the part geometry that can be achieved.

Another trade-off is the high start-up cost associated with CNC machining. Setting up the machine, loading tools, and programming CNC mills or lathes often requires a skilled technician. While this setup cost is fixed, it becomes more economical when applied to multiple parts, as the setup process can be reused. Additionally, significant savings can be realized by minimizing part repositioning. Machining with 5-axis machines and above can often be more cost-effective for parts with multiple facets, as it eliminates the need for manual repositioning, thus reducing setup time and potential errors.