Custom Wire EDM Machining Service

Wire EDM (Electrical Discharge Machining) Service: Wire EDM machining uses a thin wire electrode to cut through metal with high precision, ideal for creating complex shapes, fine details, and intricate designs in hard metals. This service is widely used in industries such as aerospace, automotive, and tooling, offering exceptional accuracy and a smooth finish without the need for traditional cutting tools.

Other CNC Machining Services

Custom Online CNC Machining Services

CNC Machining Services involve the use of Computer Numerical Control (CNC) machines to automate the precise cutting, shaping, drilling, and finishing of materials based on a digital design file. CNC machining is widely used in manufacturing industries for creating highly accurate, complex, and detailed parts. The process involves controlling the movement of machine tools using a computer, which allows for high precision, repeatability, and speed.

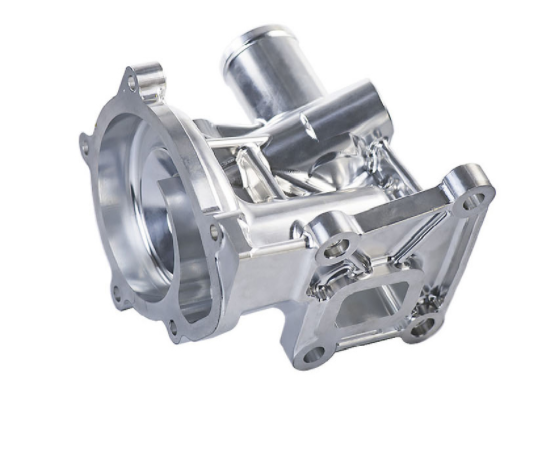

Custom CNC Milling Services

Custom CNC Milling Services involve the use of Computer Numerical Control (CNC) machines to precisely machine custom parts and components from a variety of materials. CNC milling is ideal for producing complex shapes, intricate designs, and tight tolerances for a wide range of industries, including aerospace, automotive, medical, and consumer products.

CNC Turning Service

CNC Turning Service involves the use of Computer Numerical Control (CNC) machines to precisely machine cylindrical parts by removing material from a rotating workpiece. CNC turning is ideal for creating round or cylindrical components with high precision, and is commonly used in industries such as aerospace, automotive, medical devices, and electronics.

Wire EDM Machining Finishes Available

Standard (As-Milled)

The finish option with the quickest turnaround is the as-machined finish, where CNC machined parts are left with visible tool marks and potentially sharp edges or burrs. These can be removed upon request. The surface finish is typically comparable to a 125 µin Ra finish, offering a functional surface that may require additional post-processing for smoother or more refined appearances.

Bead Blast

The part surface is left with a uniform, smooth, and matte appearance, providing a clean finish that reduces surface imperfections while maintaining a consistent texture.

Tumbled

The part surface is left with a consistent, smooth, and matte finish, reducing surface imperfections while ensuring a uniform texture.

Anodized (Type II or Type III)

- Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish, typically applied to aluminum. Parts can be anodized in various colors, with clear, black, red, and gold being the most common options.

- Type III (MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2 “hardcoat”) produces a thicker anodized layer, offering both enhanced wear resistance and the corrosion resistance of Type II. This type is ideal for applications requiring increased durability and strength. For examples of our anodized finishes, please refer to our metal finishes gallery.

Titanium Anodize

A surface finish for titanium according to the AMS-2488 Type 2 specification, also known as Tiodize. This finish enhances the fatigue strength and wear resistance of titanium parts. Titanium anodized parts are commonly used in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes result in a dull, matte shine.

PTFE Impregnated Hard Anodize

A hard coat anodizing process that incorporates PTFE (polytetrafluoroethylene) to create a self-lubricating, dry-contact surface with the protective properties of a Type 3 hard coat. This finish is suitable for aluminum alloys or titanium and enhances the service life of the product by reducing friction and wear. It conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed) specification.

Chem Film (Chromate Conversion Coating)

Chem Film provides excellent corrosion resistance and good conductivity properties, making it ideal for protecting metal surfaces. It can also serve as a base for paint adhesion. The finish often leaves the surface with a yellow or gold appearance. Chem Film adds minimal thickness, typically ranging from 0.00001″ to 0.00004″. This finish conforms to MIL-DTL-5541, TYPE I/II specifications.

Passivation

Passivation enhances the corrosion resistance of 200 and 300 series stainless steels, as well as precipitation-hardened corrosion-resistant steels. The process adds negligible thickness, typically around 0.0000001″. This finish conforms to industry standards, including ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, and AMS 2700.

Powder Coat

In the powder coating process, powdered paint is sprayed onto a part and then baked in an oven, creating a strong, wear-resistant, and corrosion-resistant finish. This method results in a more durable layer compared to standard painting techniques. A wide range of colors is available, allowing for both functional and aesthetic customization. For examples, please refer to our powder coating finishes gallery.

Electropolishing

Electropolishing is an electrochemical process that cleans steel parts, improving their appearance by making the metal brighter while also reducing corrosion. This process removes a thin layer of material, typically 0.0001″ to 0.0025″ from the surface. It conforms to ASTM B912-02 standards.

Electroless Nickel Plating

Electroless nickel plating provides a uniform nickel coating that offers enhanced protection against corrosion, oxidation, and wear, even on irregular surfaces. The process results in a brighter finish, and the thickness typically starts at 0.0001”. This finish conforms to MIL-C-26074 standards.

Silver Plating

Silver plating provides excellent solderability and electrical conductivity, making it ideal for applications requiring these properties. However, silver is susceptible to tarnishing over time. The plating conforms to AMS QQ-S-365D standards, with a typical thickness ranging from 0.00002″ to 0.0003″.

Gold Plating

Gold plating offers excellent corrosion and tarnish resistance, along with superior solderability. It is commonly used for electrical connections and other high-performance applications. The default application specifications are MIL-G-45204 and ASTM B488, CLASS 00, 0, or 1. The typical plating thickness ranges from 0.00002″ to 0.00005″.

Zinc Plating

Zinc plating provides a uniform coating that offers excellent protection against corrosion, oxidation, and wear, even on irregular surfaces. This finish is commonly used to enhance the durability of steel and iron parts. It conforms to ASTM B633-15 standards.

Why Choose Avinyaworks for 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our quality check includes visual inspection, dimensional verification, functionality testing (if applicable), and a review of surface finish.