Tube Bending Services

What is Tube Bending?

Tube bending is a critical process in manufacturing, used to shape tubes or pipes into curved forms for a variety of applications across different industries. It involves deforming a tube without compromising its structural integrity or surface finish. Tube bending can be performed using various techniques, depending on the material, the complexity of the bend, and the specific requirements of the project.

Types of Tube Bending Techniques

Rotary Draw Bending

Description: This is one of the most common and precise methods for bending tubes. The tube is fed into a die and wrapped around a mandrel to maintain its shape. This method allows for tight bends with minimal distortion, ensuring high precision and smooth internal surfaces.

Applications: Used in industries such as automotive (for exhaust systems and roll cages), aerospace (for fuel lines and structural components), and general manufacturing.

Roll Bending

- Description: In this process, the tube is passed through a set of rollers that gradually bend the tube into the desired shape. Roll bending is typically used for larger-radius bends and for materials with thicker walls.

- Applications: Used in structural applications like handrails, frameworks, and furniture manufacturing.

Compression Bending

- Description: A mandrel or form is used to compress the tube against a die, creating a bend. The material is compressed on the inside of the bend, causing the tube to stretch on the outside.

- Applications: This technique is often used for large, single-radius bends in simple applications where precise tolerances are not as critical.

Mandrel Bending

- Description: This is a variation of rotary draw bending where a mandrel (a rod or plug) is inserted into the tube to support it during the bending process. This prevents the tube from collapsing or kinking, making it ideal for tubes with thin walls or high-quality finish requirements.

- Applications: Used in industries like automotive (for exhaust systems), aerospace, and plumbing, where a smooth internal surface is critical.

Heat Bending

- Description: In this process, heat is applied to the tube, making it more pliable, and then the tube is bent manually or using a machine. The heat softens the material, allowing it to be bent without cracking.

- Applications: Suitable for thermoplastics and materials that need to be softened before bending.

Push Bending

- Description: The tube is pushed into a die while it is supported by a fixed or rotating mandrel. The tube is bent as it moves along the die. This method is usually applied to create large-radius bends.

- Applications: Often used for bending larger diameter pipes and tubes used in construction or infrastructure projects.

Tube Bending Material Options

Tube bending services are for creating custom round tubes in a variety of shapes and materials:

- Stainless Steel 304 and 316 (Welded or Seamless) are resistant to rust and corrosion, making them ideal for outdoor, wet, or salty environments. 316 has slightly better corrosion resistance than 304.

- Aluminum 6061 (Extruded or Drawn) is a stiff, lightweight tube that won’t rust. It it heavily used in lightweight frames and aircraft parts.

- Alloy Steel 4130 (Seamless) is an extremely strong and tough tube used in race cars and aerospace structures. Seamless reduces failure points in this material making ideal for critical applications.

- Steel A513 (Type 1 HREW, Type 2 CREW, or Type 5 DOM) is a go-to for general use. DOM is smooth and strong for car parts; HREW is less expensive and good for simple structures; CREW is cold-formed for better strength and finish.

Round Tubing

| Material | Minimum O.D. | Maximum O.D. | Minimum wall thickness | Maximum wall thickness |

|---|---|---|---|---|

|

Stainless Steel 304 |

.250″ |

2.000″ |

.035″ |

.188″ |

|

Stainless Steel 316 |

.250″ |

2.000″ |

.035″ |

.120″ |

|

Aluminum 6061 |

.250″ |

2.000″ |

.035″ |

.188″ |

|

Steel 4130 (Chromoly) |

.375″ |

2.000″ |

.035″ |

.188″ |

|

Steel A513 Type 5, DOM |

.250″ |

2.000″ |

.035″ |

.188″ |

|

Steel A513 Type 1, HREW |

1.000″ |

2.000″ |

.065″ |

.120″ |

|

Steel A513 Type 2, CREW |

.500″ |

2.000″ |

.035″ |

.065″ |

Tube Glossary

- Welded tube is made by rolling a flat piece of metal into a tube shape and then welding the edges together.

- Seamless tube is made without any welding. It's formed by heating and stretching a solid piece of metal until it becomes a tube.

- Extruded tube is made by pushing heated metal through a shaped opening. This process can create complex shapes and is commonly used for aluminum.

- Drawn tube is made by pulling a tube through a smaller die, making it more precise and stronger. Extruded and welded tube stock can be drawn.

- Drawn Over Mandrel is like drawn where welded tube is drawn over a mandrel after welding to improve strength and finish.

- Hot Rolled Electric-Welded tube is made from hot-rolled steel. This is a less expensive tube used for general purposes.

- Cold Rolled Electric-Welded is similar to HREW but made from cold-rolled steel giving it a slightly better surface compared to HREW.

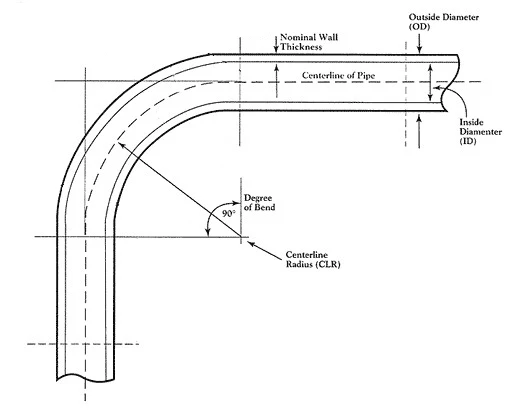

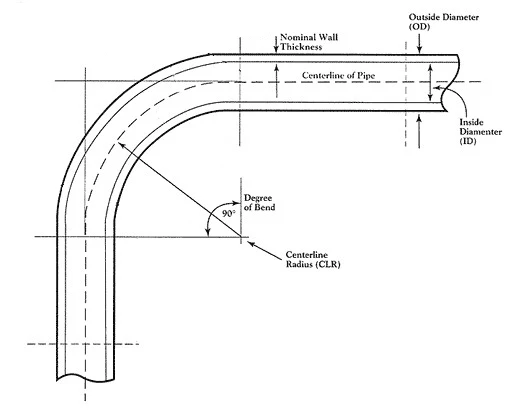

Tube Bending Sizes and Tolerances

- Minimum bendable tube diameter: .250"

- Maximum bendable tube diameter: 2.000"

- Minimum bendable tube wall thickness: .035"

- Maximum bendable tube wall thickness: .188"

- Overall tube sheath envelope tolerance is +/- 0.125” typical

- Linear dimensions (excluding locations to bends) are +/- 0.010"

- Simple, single planar bends are +/- 0.010”

- Multiple surface or multi-planar bends are +/- 0.030”

- Tube center line radius tolerance is +/- 0.125” typical

Applications Tube Bending

Benefits of Tube Bending

Design Flexibility

Tube bending allows for complex shapes and custom geometries that are hard to achieve with other manufacturing techniques.

Cost-Efficiency

By eliminating the need for welding, joining, or assembly of multiple parts, tube bending can be a more cost-effective solution for creating tubular components.

Improved Strength

Bending can provide structural strength to tubes and pipes, which is particularly useful in load-bearing applications.

Customization

Tube bending is highly adaptable to specific project requirements, from custom radii and angles to specific material types and wall thicknesses.

Why Choose Avinyaworks for Tube Bending?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Expert Help

Our team of Solutions Engineers and Process Specialists is here to support you every step of the way.