Custom Plastic Fabrication

What is Custom Plastic Fabrication?

Custom plastic fabrication refers to the process of designing and manufacturing plastic products or components to meet specific, tailored requirements. Unlike mass-produced plastic items, custom plastic fabrication allows for the creation of unique shapes, sizes, and features that are not available in standard products. This process involves a range of fabrication techniques, including injection molding, CNC machining, thermoforming, and welding, among others, to transform raw plastic materials into functional, bespoke items. These custom products are often designed to fit exact specifications, allowing them to serve specialized functions or applications across various industries, such as medical devices, automotive parts, and electronics enclosures.

Techniques and Equipment Used in Plastic Fabrication

Techniques

Plastic fabrication involves several techniques that are used to shape, mold, and assemble plastic materials into various products. Some of the key techniques include:

Injection Molding

This process involves injecting molten plastic into a mold to create a specific shape. It’s ideal for producing high-volume parts with complex designs.

Extrusion

In this technique, plastic is heated and forced through a mold to create long, continuous shapes like pipes, sheets, or profiles.

CNC Machining

Computer Numerical Control (CNC) machines are used to precisely cut, drill, and shape plastic materials based on a digital design, providing high accuracy and repeatability.

Vacuum Forming

This method uses heat to soften a plastic sheet, which is then vacuum-formed over a mold to create various shapes, such as packaging or covers.

Thermoforming

Similar to vacuum forming, thermoforming involves heating a plastic sheet until soft and then shaping it using molds, often for larger items like containers or automotive parts.

Equipment

Compression Molding Machines

These machines are used for molding thermosetting plastics by placing the material in a mold and applying heat and pressure to shape the plastic. It’s commonly used for creating automotive parts, electrical components, and household items.

Heat Sealing Machines

These machines are used to seal plastic components together by applying heat to the surfaces to fuse them, often used in packaging and other industries requiring airtight or watertight seals.

Plastic Shearing Machines

These are used to cut plastic sheets, rods, or pipes into precise shapes and sizes, typically by applying a shear force to the material.

Ultrasonic Welding Machines

Used for joining plastic parts, ultrasonic welding relies on high-frequency ultrasonic vibrations to generate heat, which melts the plastic and bonds the parts together without using any adhesives.

Punch Press Machines

These machines are used to create holes, shapes, and patterns in plastic sheets or parts by applying a press force through a die, commonly used for creating holes in plastic panels or sign materials.

Plastic Fabrication Advantages and Disadvantages

Advantages of Plastic Fabrication

Compression Molding Machines

These machines are used for molding thermosetting plastics by placing the material in a mold and applying heat and pressure to shape the plastic. It’s commonly used for creating automotive parts, electrical components, and household items.

Heat Sealing Machines

These machines are used to seal plastic components together by applying heat to the surfaces to fuse them, often used in packaging and other industries requiring airtight or watertight seals.

Plastic Shearing Machines

These are used to cut plastic sheets, rods, or pipes into precise shapes and sizes, typically by applying a shear force to the material.

Ultrasonic Welding Machines

Used for joining plastic parts, ultrasonic welding relies on high-frequency ultrasonic vibrations to generate heat, which melts the plastic and bonds the parts together without using any adhesives.

Disadvantages of Plastic Fabrication

Environmental Impact

The production and disposal of plastic materials can contribute to environmental pollution, particularly when plastics are not properly recycled. Many plastics are not biodegradable, leading to long-term waste accumulation in landfills and oceans.

Material Limitations

Although plastic is versatile, it may not be suitable for all applications. Certain types of plastic may not have the same strength, heat resistance, or durability as metals or other materials, limiting their use in high-stress or high-temperature environments.

Vulnerable to Degradation

Some plastics, especially those exposed to UV light or harsh chemicals, can degrade over time. This can lead to cracking, discoloration, and reduced strength, limiting the lifespan of plastic products in certain conditions.

Quality Variability

The quality of plastic products can sometimes vary due to issues with material consistency or manufacturing processes. This may lead to defects, such as air bubbles, inconsistent finishes, or dimensional inaccuracies.

Industries Served by Plastic Fabrication

Display

Plastic fabrication is used to produce display fixtures, point-of-sale (POS) materials, and packaging for retail businesses. Plastics provide an aesthetic appeal and are easy to fabricate into custom shapes for creating visually engaging displays and packaging solutions.

Utilities

The energy sector uses plastic fabrication for creating components such as pipes, fittings, and tanks for oil, gas, and water systems. Plastics offer resistance to corrosion, high pressure, and harsh chemicals, which are essential in energy-related applications.

Automotive

Plastic fabrication is used extensively in the automotive industry for manufacturing lightweight parts, including dashboards, bumpers, door panels, and under-the-hood components. Plastics provide strength, durability, and resistance to heat, chemicals, and weathering, making them ideal for automotive applications.

Packaging

The packaging industry uses plastic fabrication to create a wide variety of containers, bottles, trays, and films. Plastics are lightweight, versatile, and can be molded into custom shapes, making them ideal for packaging everything from food and beverages to pharmaceuticals and consumer goods.

Construction

In the construction industry, plastic fabrication is used to create piping, insulation, windows, doors, and flooring materials. Plastics offer durability, resistance to corrosion, and thermal efficiency, making them a cost-effective and low-maintenance alternative to traditional materials like wood or metal.

Advertising

Plastic fabrication is widely used in creating signs, displays, and advertising materials, including illuminated signs, point-of-purchase displays, and exhibition stands. Plastics offer versatility in design, durability, and ease of customization, making them ideal for visual communication needs.

Alternatives to Plastic Fabrication

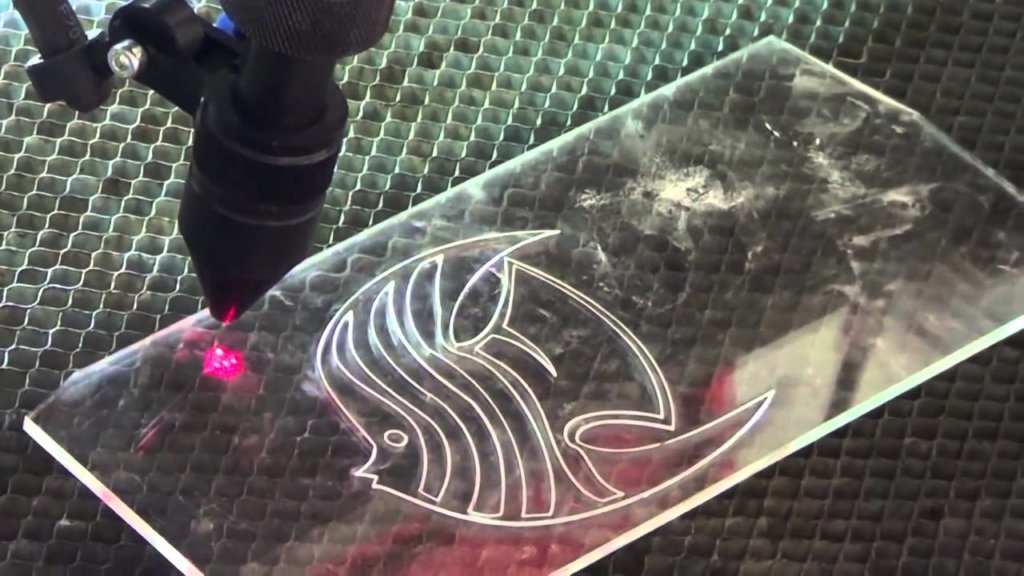

Glass Fabrication

- Materials: Glass, tempered glass, and glass composites.

- Advantages: Glass is transparent, durable, and has excellent optical properties. It is widely used in applications like windows, displays, containers, and architectural elements.

- Processes: Glass fabrication involves cutting, shaping, tempering, laminating, and polishing glass to meet specific requirements.

Ceramic Fabrication

- Materials: Clay, porcelain, and advanced ceramics (e.g., silicon carbide, alumina).

- Advantages: Ceramics are heat-resistant, chemically stable, and strong under compression. They are used in high-temperature applications, electronics, medical devices, and construction.

- Processes: Ceramic fabrication involves molding, drying, firing, glazing, and finishing.

Rubber Fabrication

- Materials: Natural rubber, synthetic rubber, and elastomers.

- Advantages: Rubber is flexible, durable, and resistant to wear and weathering. It is commonly used for seals, gaskets, tires, and other products requiring elasticity and shock absorption.

- Processes: Rubber fabrication includes molding, extrusion, vulcanization, and cutting.

Textile Fabrication

- Materials: Fabrics such as cotton, wool, polyester, nylon, and other fibers.

- Advantages: Textiles are versatile, lightweight, and often biodegradable, with applications in clothing, upholstery, and industrial products.

- Processes: Textile fabrication involves weaving, knitting, stitching, and finishing.

Why Choose Avinyaworks for Custom Plastic Fabrication?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our quality check includes visual inspection, dimensional verification, functionality testing (if applicable), and a review of surface finish.