Material Selection Guide

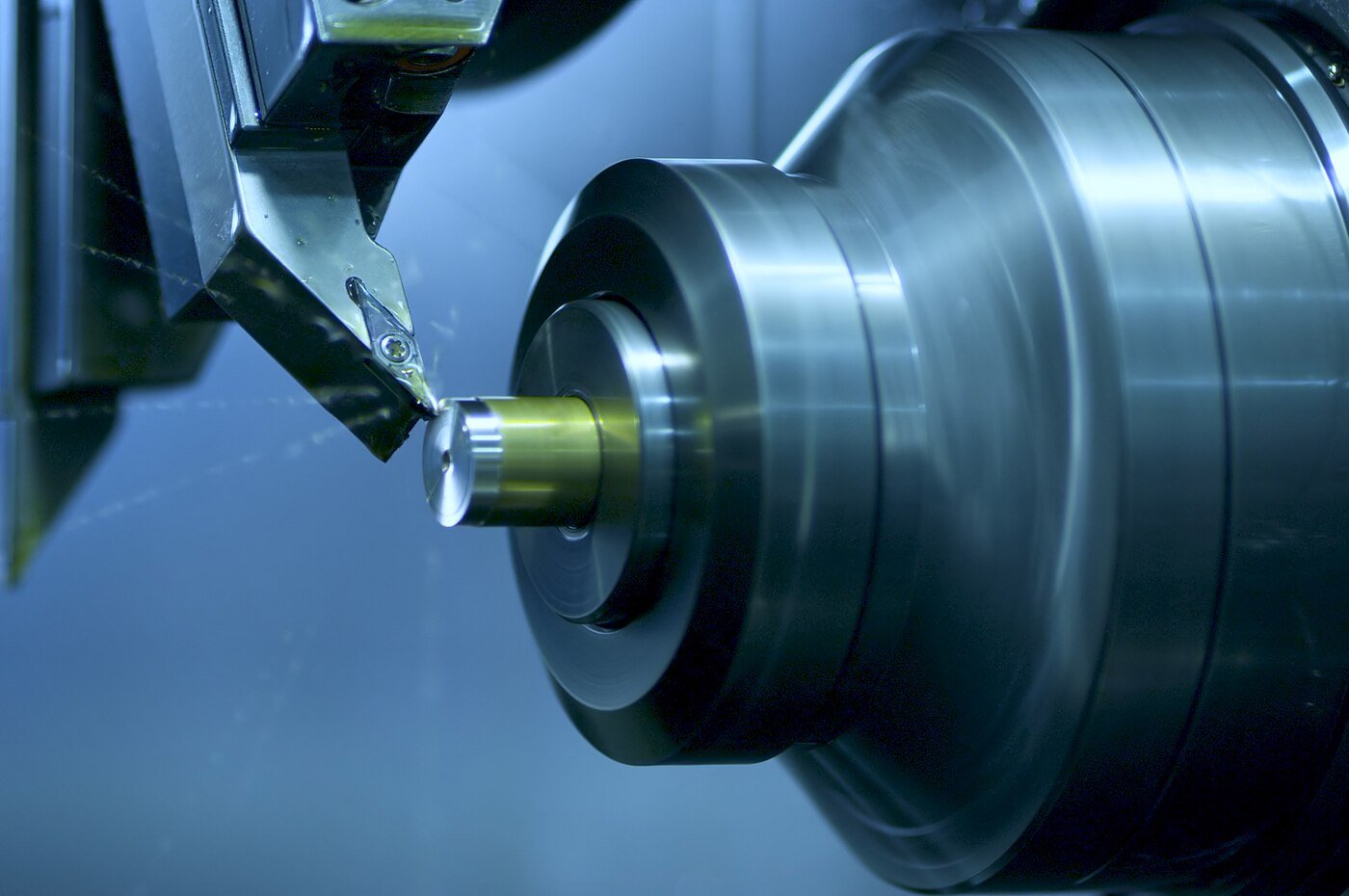

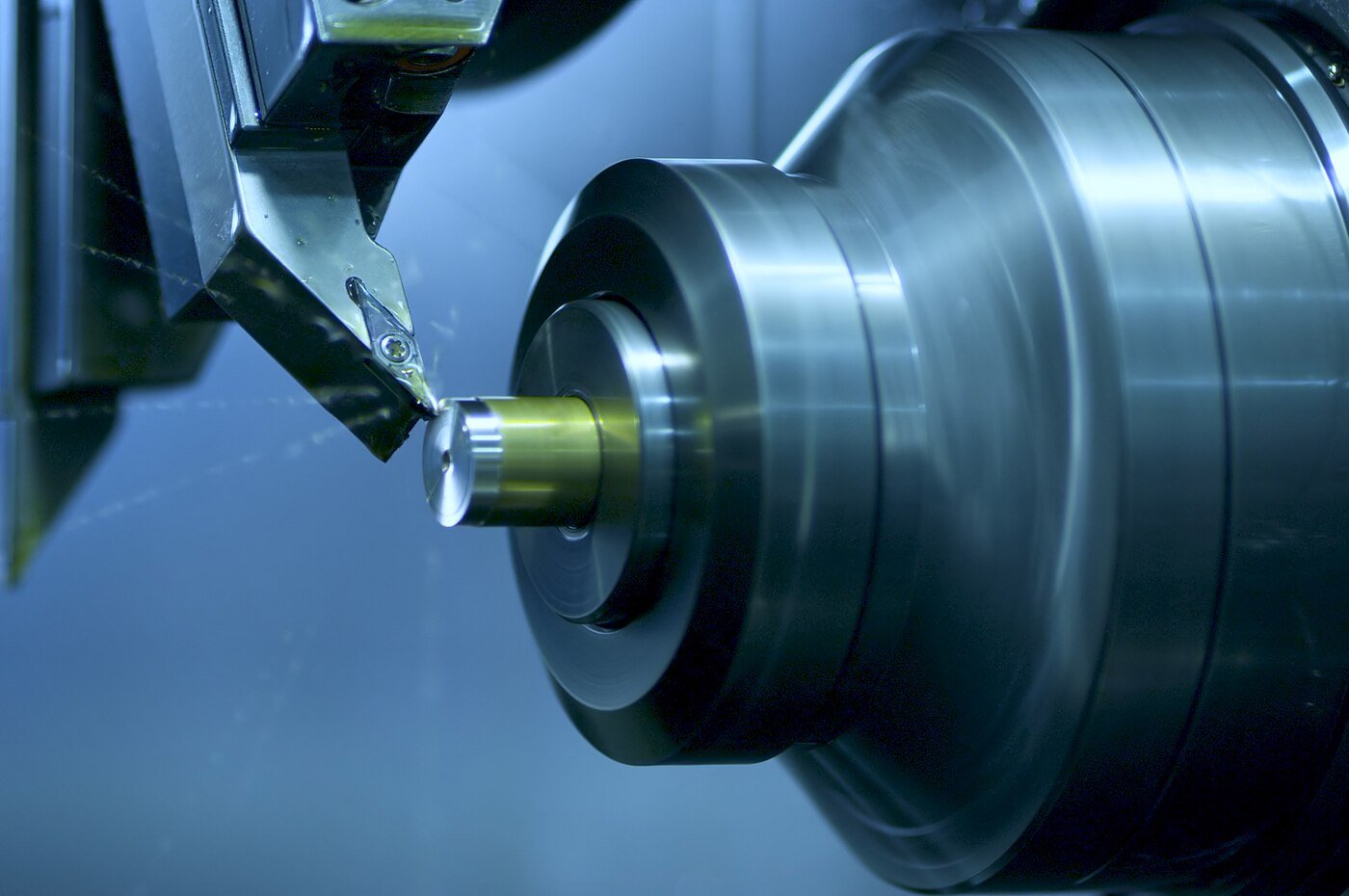

CNC Metal Materials

Aluminum, stainless, steels, titanium alloys, and more.

CNC Plastic Materials

Acetal, ABS, nylon, HDPE, PP, PEEK, PTFE, and more.

CNC Composite Material

CNC Composite Materials and more

Sheet Metal Materials

Aluminum, stainless, steel, and copper alloys.

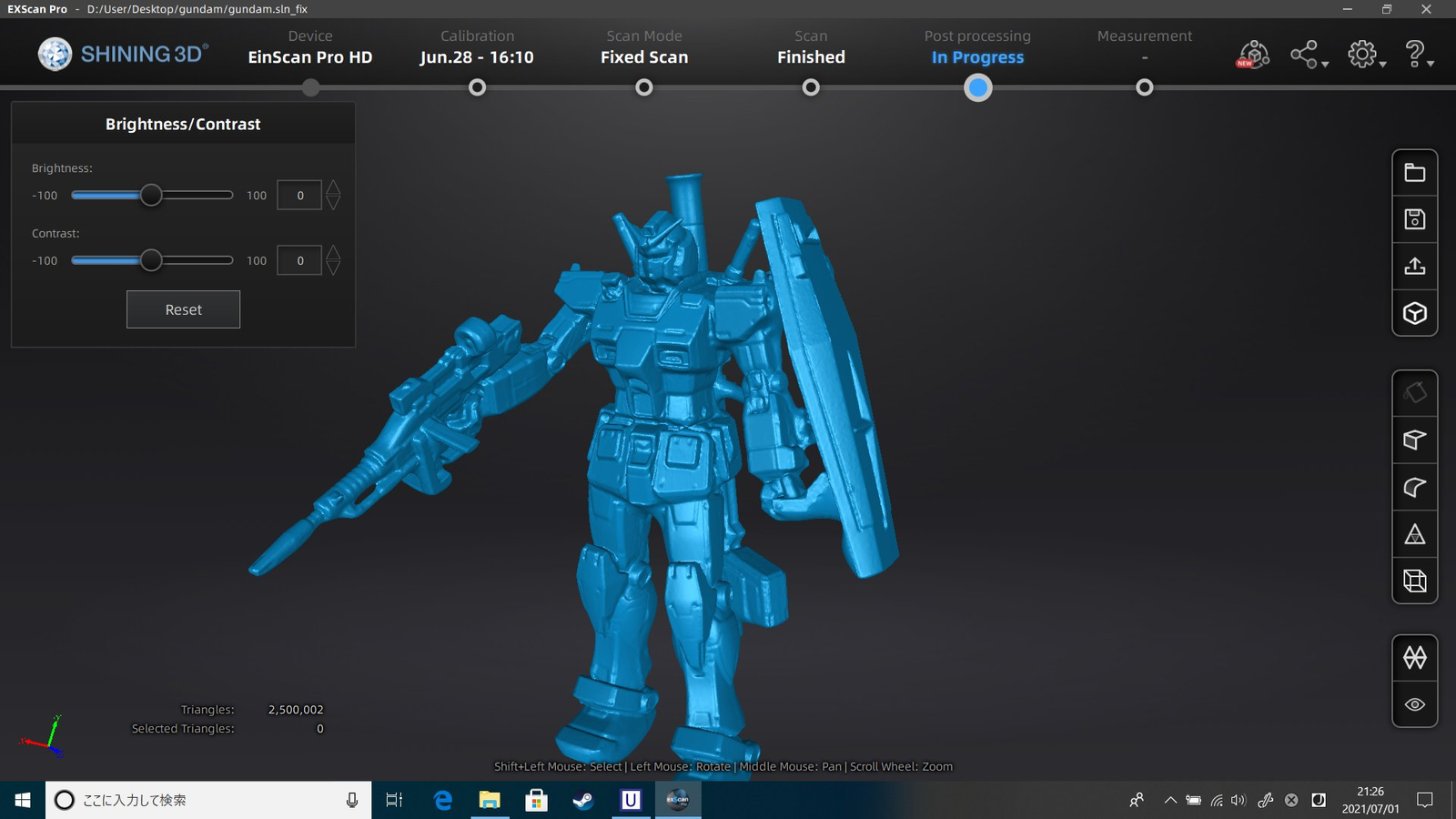

3D Printed Metals

Aluminum, stainless steel alloys, metal composites, and more.

3D Printed Plastics

Engineering plastics like ABS, nylon, ULTEM, PC, as well as photopolymers.

3D Printed Resins

Carbon DLS, SLA, Nexa3D LSPc, and PolyJet resins

Cast Urethane Materials

Rigid, rubbery, flame retardent, and more durable urethanes.

Injection Molded Plastics

Commodity plastics like ABS, PC-ABS, as well as high performing PEEK and more.

Sheet Cut Foam Materials

EVA Foam, Extra Soft PU, Flame Retardant Foams, and more

Sheet Cut Wood Materials

Hardwoods, Masonite, Plywood, and more

Sheet Cut Rubber Materials

Buna-N Rubber Blends, EPDM, Silicone Rubber, Paper Fiber, PTFE

Metal Finishing Services Offered by Avinyaworks

Sandblasted Finish

A textured, matte surface created by blasting fine particles onto the metal.

Electroplating

A coating of another metal (e.g., gold, silver, or nickel) for enhanced appearance and protection.

Bead Blasting

A smooth, satin-like finish achieved by blasting small glass beads.

Oil-Rubbed Finish

A hand-applied finish that gives metal a dark, aged appearance.

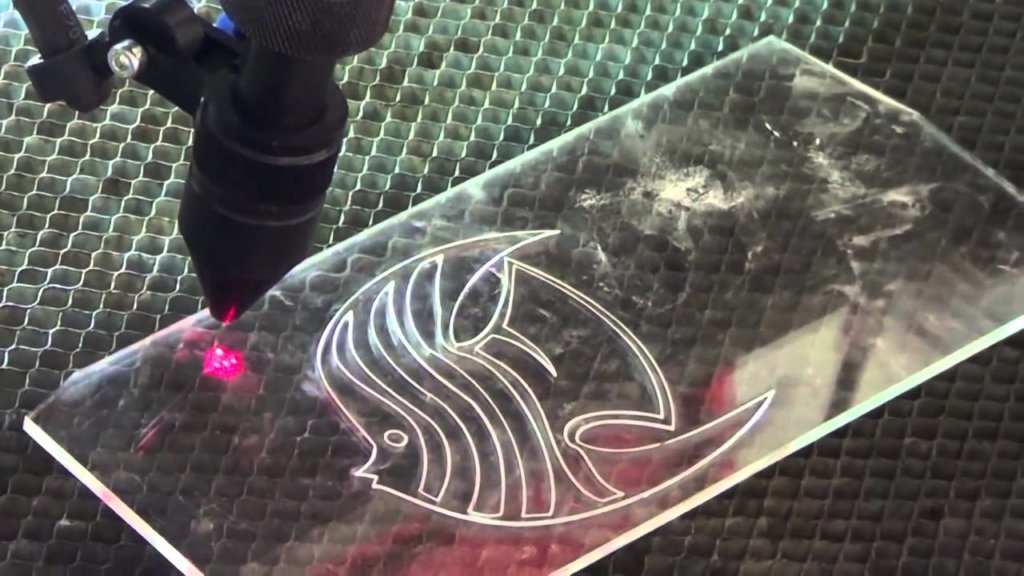

Etched Finish

Unique patterns or textures created by acid or laser etching.

Vibratory Finish

A uniform matte or polished effect achieved through vibratory tumbling.

Popular Finishes for Metal

Brushed Finish

A sleek, matte look achieved by fine abrasive brushing, commonly used for stainless steel.

Polished Finish

A reflective, shiny surface achieved by buffing, ideal for decorative purposes

Powder Coating

Durable, colored finish applied as a powder and baked for a smooth, even coat.

Anodizing

Electrochemical process that enhances corrosion resistance and allows color options for aluminum.

Patina Finish

A natural or chemically induced aged effect for a rustic or antique look.

Our Manufacturing Standards

At Avinyaworks, we adhere to the highest manufacturing standards to ensure excellence in every project. Our processes are built on precision, quality control, and innovation. We use state-of-the-art equipment and expert craftsmanship to deliver durable, functional, and aesthetically superior finishes. Every product undergoes rigorous testing to meet industry specifications, ensuring consistency and reliability in every detail.

Workmanship Standards

At Avinyaworks, our workmanship standards are built on a foundation of excellence, precision, and dedication. We are committed to delivering superior results through expert craftsmanship and stringent quality assurance. Our core principles include:

Accuracy: Every product is created with meticulous attention to detail and precise measurements.

Consistent Quality: Rigorous inspections throughout the process ensure uniformity and premium quality.

Expert Crafting: Our skilled team brings unparalleled expertise to achieve exceptional finishes.

Premium Materials: Only top-tier materials are used to ensure superior durability and visual appeal.

Efficiency: We prioritize completing projects within the specified time frame, maintaining high standards.

Sustainability: We implement eco-conscious methods and materials to minimize environmental impact.

Standard Sheet Sizes

Avinyaworks provides sheet cutting services, offering both laser cutting and waterjet cutting solutions. These services are designed to meet a wide range of material needs. The following tables outline the various materials available, along with the standard gauge thickness options for each. These guides help ensure the right fit for your specific cutting requirements, providing flexibility and precision for your projects.

Sheet Metal Services: Cutting and Shaping

Laser Cutting

Sheet Metal Forming

Welding and Assembly

Welding and assembly services join metal parts to create custom structures with strength and precision.

Powder Coating

Powder coating provides durable, vibrant finishes that enhance appearance while offering corrosion resistance.

Standard Tube Sizes

Round Tube

Aluminum Round Stock

Rectangular Tube

Stainless Steel

Alloy Steel

Standard Threads

Internal Threads

| Thread | Hole Diameter(in) | Max Thread Depth(in) |

|---|---|---|

|

0-80 UNC

|

0.047

|

0.157

|

|

1-64 UNC

|

0.059

|

0.177

|

|

2-56 UNC

|

0.070

|

0.306

|

|

2-64 UNF

|

0.070

|

0.306

|

|

4-40 UNC

|

0.089

|

0.394

|

|

4-48 UNF

|

0.094

|

0.394

|

|

5-40 UNC

|

0.102

|

0.438

|

|

5-44 UNF

|

0.104

|

0.438

|

|

6-32 UNC

|

0.107

|

0.481

|

|

6-40 UNF

|

0.113

|

0.481

|

|

8-32 UNC

|

0.136

|

0.525

|

|

8-36 UNF

|

0.136

|

0.525

|

|

10-24 UNC

|

0.150

|

0.612

|

|

10-32 UNF

|

0.159

|

0.612

|

|

1/4-20 UNC

|

0.201

|

0.750

|

|

1/4-28 UNF

|

0.213

|

0.750

|

|

5/16-18 UNC

|

0.257

|

0.844

|

|

5/16-24 UNF

|

0.272

|

0.844

|

|

3/8-16 UNC

|

0.313

|

0.938

|

|

3/8-24 UNF

|

0.332

|

0.938

|

|

7/16-14 UNC

|

0.368

|

1.078

|

|

7/16-20 UNF

|

0.391

|

1.078

|

|

1/2-13 UNC

|

0.422

|

1.242

|

|

1/2-20 UNF

|

0.453

|

1.242

|

|

9/16-12 UNC

|

0.484

|

1.250

|

|

9/16-18 UNF

|

0.500

|

1.250

|

|

5/8-11 UNC

|

0.531

|

1.250

|

|

5/8-18 UNF

|

0.563

|

1.250

|

|

3/4-10 UNC

|

0.656

|

1.250

|

|

3/4-16 UNF

|

0.688

|

1.250

|

| Metric | Hole Diameter(in) | Max Thread Depth(in) |

|---|---|---|

|

M2x0.4

|

0.063

|

0.306

|

|

M2.5×0.45

|

0.081

|

0.350

|

|

M3x0.5

|

0.098

|

0.438

|

|

M3.5×0.6

|

0.114

|

0.481

|

|

M4x0.7

|

0.130

|

0.525

|

|

M5x0.8

|

0.165

|

0.612

|

|

M6x1.0

|

0.197

|

0.750

|

|

M8x1.25

|

0.264

|

0.900

|

|

M10x1.5

|

0.335

|

0.938

|

|

M12x1.75

|

0.402

|

1.242

|

External Threads

| Thread | Boss Diameter (in) | Max Thread Length (in) |

|---|---|---|

|

UNC/UNF

|

||

|

2-56 UNC

|

0.086

|

0.20

|

|

2-64 UNF

|

0.086

|

0.20

|

|

4-40 UNC

|

0.112

|

0.22

|

|

4-48 UNF

|

0.112

|

0.22

|

|

5-40 UNC

|

0.125

|

0.25

|

|

5-44 UNF

|

0.125

|

0.25

|

|

6-32 UNC

|

0.138

|

0.28

|

|

6-40 UNF

|

0.138

|

0.28

|

|

8-32 UNC

|

0.164

|

0.33

|

|

8-36 UNF

|

0.164

|

0.33

|

|

10-24 UNC

|

0.190

|

0.38

|

|

10-32 UNF

|

0.190

|

0.38

|

|

1/4-20 UNC

|

0.250

|

0.50

|

|

1/4-28 UNF

|

0.250

|

0.50

|

|

5/16-18 UNC

|

0.313

|

0.675

|

|

5/16-24 UNF

|

0.313

|

0.675

|

|

3/8-16 UNC

|

0.375

|

0.75

|

|

3/8-24 UNF

|

0.375

|

0.75

|

|

7/16-14 UNC

|

0.438

|

0.875

|

|

7/16-20 UNF

|

0.438

|

0.875

|

|

1/2-13 UNC

|

0.500

|

1.00

|

|

1/2-20 UNF

|

0.500

|

1.00

|

|

9/16-12 UNC

|

0.563

|

1.25

|

|

9/16-18 UNF

|

0.563

|

1.25

|

Standard Inserts

Thread Maximum Insert Length and Hole Diameter

| Thread | Maximum Insert Length (in) | Hole Diameter (in) |

|---|---|---|

| UNC/UNF | ||

| 0-80 UNC | 0.125 | 0.094 |

| 2-56 UNC | 0.156 | 0.125 |

| 4-40 UNC | 0.188 | 0.156 |

| 6-32 UNC | 0.250 | 0.188 |

| 8-32 UNC | 0.313 | 0.219 |

| 10-24 UNC | 0.375 | 0.250 |

| 10-32 UNF | 0.375 | 0.250 |

| 1/4-20 UNC | 0.500 | 0.313 |

| 5/16-18 UNC | 0.563 | 0.375 |

| 3/8-16 UNC | 0.625 | 0.438 |

| Thread | Boss Diameter (in) | Max Thread Length (in) |

|---|---|---|

| Metric | ||

| M3x0.5 | 0.189 | 0.157 |

| M3.5×0.6 | 0.252 | 0.189 |

| M4x0.7 | 0.315 | 0.220 |

| M5x0.8 | 0.374 | 0.252 |

| M6x1.0 | 0.500 | 0.315 |

Why Choose Avinyaworks ?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Avinyaworks ensures aerospace and defence quality with advanced testing and tailored solutions for reliability and safety.