CNC Routing Services

CNC Routing Service

Whether you need intricate designs, custom patterns, or simple cuts, our CNC routers are capable of delivering exceptional results with tight tolerances. Our experienced team ensures quick turnaround times, allowing you to meet your project deadlines with ease. With versatile material capabilities and high customization options, CNC routing is perfect for industries such as signage, furniture, aerospace, and more.

Our CNC Routing Services offer precision machining for a wide range of materials, including wood, plastics, composites, and non-ferrous metals. Using advanced CNC routers, we provide fast, efficient, and high-quality cutting, engraving, and shaping for both prototypes and production runs. CNC routing is ideal for producing complex shapes and large-scale components with high accuracy and repeatability.

CNC Processes

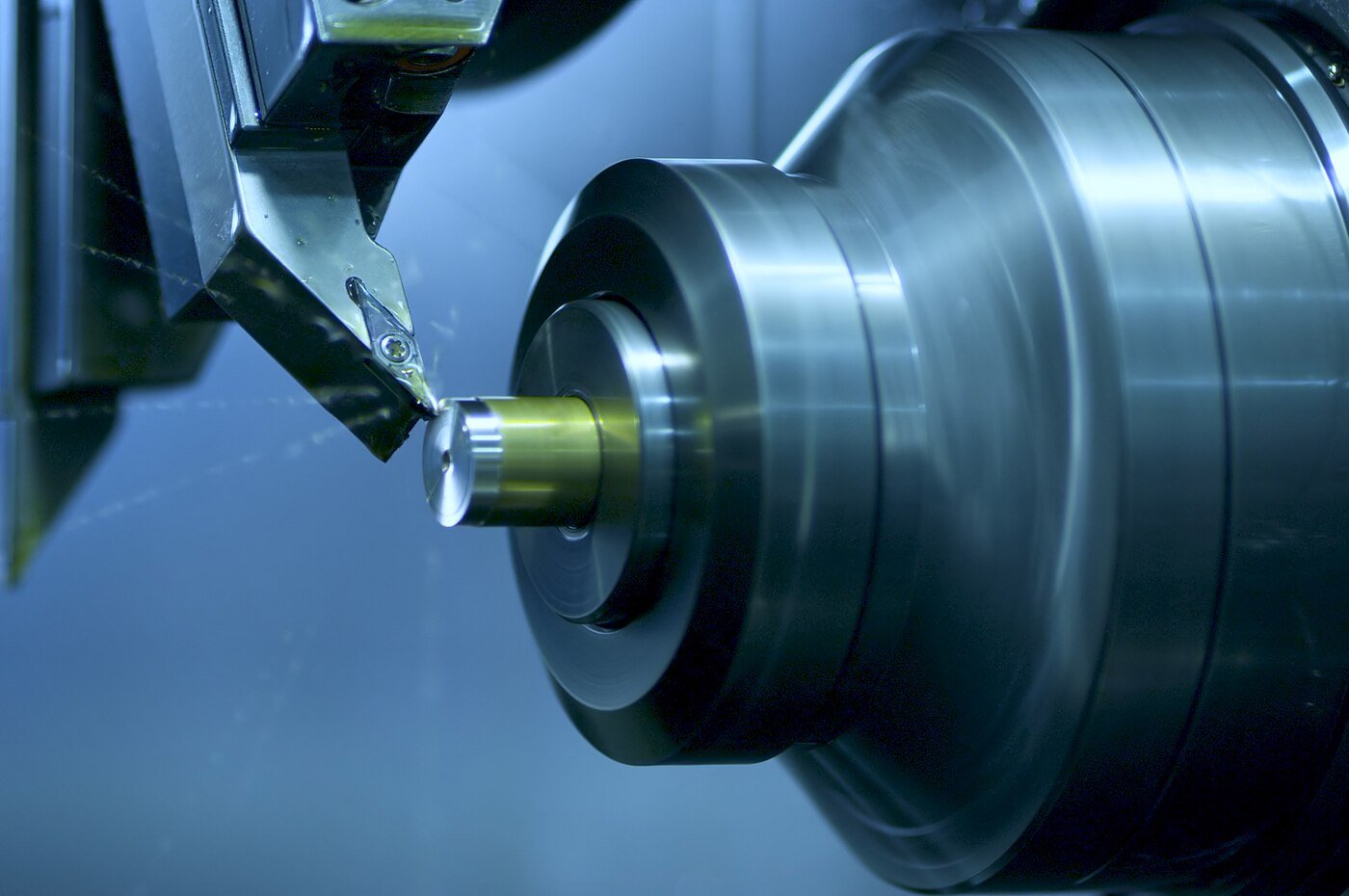

Cutting Tool: In CNC routing, a rotating router bit is the primary cutting tool, designed to cut through materials like wood, plastics, and composites.

Material Orientation: CNC routing machines are primarily designed to work with flat or sheet materials, such as plywood, acrylic sheets, and other similar substrates, which are securely fastened to a flat table.

Cutting Direction: CNC routing machines primarily operate along the X and Y axes, cutting along the material’s plane.

Applications: While there is some overlap, CNC routing is typically associated with applications that involve large-scale cutting, such as furniture manufacturing, sign making, cabinetry, and custom wood or plastic fabrication.

Advantages of CNC Routing

CNC (Computer Numerical Control) routing has a number of significant advantages, especially in precision and efficiency when working with various materials. Some of the key benefits of CNC routing include:

Precision and Accuracy

- CNC routers offer incredibly precise cuts and designs, reducing the chances of human error. The automated system follows exact specifications, ensuring consistent and highly accurate results across multiple pieces.

- High precision is essential for complex patterns, detailed designs, and creating products with tight tolerances.

Increased Efficiency and Speed

- CNC routers can operate continuously with minimal downtime, producing parts faster than manual routing methods.

- The process is automated, meaning that once the design is programmed, the router can work autonomously, significantly reducing production time and increasing overall productivity.

Complex Designs and Customization

- CNC routers can handle intricate and complex designs that would be time-consuming or impossible with traditional methods.

- They allow for high levels of customization, making them ideal for one-off pieces, custom orders, or producing highly detailed patterns.

Consistency and Reproducibility

- Once a program is set, CNC routers can produce identical parts or products repeatedly with no variation, ensuring uniform quality across large batches of parts.

- This consistency is particularly valuable for mass production or when scaling up manufacturing processes.

Reduced Labor Costs

- Automation reduces the need for skilled labor to manually control machinery. Operators only need to monitor the machine’s progress, which reduces labor costs and minimizes the chance of operator error.

- The machine can also perform tasks that may require more than one person to complete in traditional methods.

Enhanced Safety

- CNC routers are generally safer than manual machines because they are automated and often enclosed, protecting operators from direct contact with cutting tools.

- Modern machines have built-in safety features that stop the router if a malfunction or safety hazard is detected.

Common Materials for CNC Routing

ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene) is a durable thermoplastic polymer known for its toughness and excellent impact resistance. It is widely used in various applications, including prototyping, automotive components, enclosures, and consumer products. ABS is valued for its strong structural integrity, ease of machining, and availability in a range of colors. Additionally, it is cost-effective, making it a popular choice for both industrial and commercial use. Its combination of strength, durability, and versatility makes ABS ideal for products that require resilience and high performance.

ACM Panel (Aluminum Composite Material)

ACM Panel (Aluminum Composite Material) is a lightweight composite material made up of a thin aluminum sheet fused to a core of polyethylene or fire-retardant material. It is commonly used in applications such as signage, architectural cladding, exhibition displays, and interior design. ACM panels are known for their excellent flatness, high strength-to-weight ratio, weather resistance, and ease of fabrication, making them ideal for both indoor and outdoor applications. Their versatility in shaping and cutting, combined with durability, makes ACM panels a popular choice for projects requiring long-lasting performance and aesthetic appeal.

Baltic Birch Plywood

Baltic Birch Plywood is a high-quality plywood made from multiple layers of birch veneer, renowned for its exceptional strength and durability. It is commonly used in applications such as furniture, cabinetry, jigs, and decorative items. Baltic birch plywood is known for its stability, void-free construction, and high strength, making it ideal for projects that require reliable performance. Its excellent screw-holding ability, combined with its smooth surface, allows for precise cuts and intricate engraving, making it a preferred choice for both functional and aesthetic purposes.

HDPE (High-Density Polyethylene)

HDPE (High-Density Polyethylene) is a versatile thermoplastic known for its exceptional strength-to-weight ratio and outstanding resistance to chemicals. It is commonly used in applications such as kitchen cutting boards, marine components, wear strips, and storage containers. HDPE is lightweight, highly resistant to chemicals, and exhibits low moisture absorption, making it ideal for both indoor and outdoor environments. Additionally, it is easy to machine, durable, and cost-effective, making it a popular choice for a wide range of industries requiring reliable performance and long-lasting durability.

MDF (Medium-Density Fiberboard)

MDF (Medium-Density Fiberboard) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, which are then combined with resin and compressed to form a dense, uniform board. MDF is widely used in applications such as cabinetry, furniture, signage, and decorative panels. One of its key advantages is its smooth, consistent surface, which makes it ideal for precise machining and finishing. It is highly machinable, allowing for easy shaping and carving. Additionally, MDF is known for its affordability, stability, and suitability for painting, veneering, and other finishing processes.

Polycarbonate

Polycarbonate is a transparent thermoplastic renowned for its exceptional impact resistance and optical clarity. It is commonly used in applications such as protective screens, machine guards, lenses, and electronic components. Polycarbonate offers excellent durability, high optical clarity, and is easy to shape and form, making it ideal for complex designs. Additionally, it has good electrical insulation properties and is lightweight, providing a versatile solution for both industrial and consumer products that require strength and clarity.

Foam

CNC routing is commonly used for cutting and shaping foam materials like expanded polystyrene (EPS) and polyurethane foam. Foam is widely utilized in applications such as packaging, insulation, theatrical props, and architectural modeling. Its versatility makes it ideal for creating lightweight, detailed designs, and CNC routing allows for precise and intricate cuts, ensuring high-quality results in both functional and creative projects.

UHMW (Ultra-High Molecular Weight Polyethylene)

UHMW (Ultra-High Molecular Weight Polyethylene) is a tough, abrasion-resistant thermoplastic known for its high molecular weight. It is commonly used in applications such as bearings, wear strips, conveyor components, and chute liners. UHMW offers outstanding abrasion resistance, self-lubricating properties, low friction, and high impact strength, making it ideal for demanding environments where durability and performance are essential. Its resistance to wear and tear, combined with its ability to perform in harsh conditions, makes UHMW a preferred choice for industrial applications.

Aluminum

Aluminum is a lightweight metal recognized for its strength, corrosion resistance, and excellent conductivity. It is widely used in applications such as machine parts, household hardware, automotive components, and enclosures. Aluminum offers a high strength-to-weight ratio, making it ideal for lightweight yet durable structures. Additionally, it has excellent thermal and electrical conductivity and is highly resistant to corrosion, making it suitable for both indoor and outdoor environments and ideal for a variety of industries requiring reliability and performance.

Brass

Brass is an alloy made of copper and zinc, valued for its attractive appearance, ease of machinability, and versatility. It is commonly used in applications such as decorative items, jewelry, hardware, and musical instruments. Brass offers excellent corrosion resistance, making it ideal for both indoor and outdoor environments. Additionally, it possesses antimicrobial properties, making it a preferred choice for applications in healthcare, plumbing, and environments requiring hygiene and durability. Its combination of aesthetic appeal and practical benefits makes brass a popular material across various industries.

Composites

CNC routing is commonly employed to process composite materials such as fiberglass-reinforced plastic (FRP), carbon-fiber-reinforced plastic (CFRP), and other composite laminates. CFRP, in particular, is known for its high strength-to-weight ratio, excellent stiffness, and superior fatigue resistance. It also has low thermal expansion, making it ideal for applications that require durability under extreme conditions. CFRP is widely used in industries such as aerospace, automotive, marine, and sports equipment, where its lightweight yet strong properties are crucial for performance and reliability.

Applications of CNC Routing

- Wooden Furniture: CNC routing is widely utilized in the production of wooden furniture, enabling precise cutting, shaping, and intricate designs for high-quality craftsmanship.

- Signage: CNC routing is frequently used in the creation of custom signage for businesses, organizations, and events, offering precise cuts and intricate designs for eye-catching displays.

- Molds for Thermoforming: Thermoforming is a manufacturing process where a plastic sheet is heated and shaped over a mold to create precise and consistent designs for various applications.

- Cabinetry and Millwork: CNC routing is widely used in the production of cabinetry and millwork components, ensuring precision, intricate detailing, and high-quality finishes for custom furniture and interior designs.

- Automotive and Aerospace Components: CNC routing is utilized in the manufacturing of automotive and aerospace components, providing high precision, intricate detailing, and consistency for critical parts and assemblies.

Why Choose Avinyaworks For CNC Turning Service?

Endless Options

Choose from a vast array of material options, finishes, tolerances, markings, and certifications to customize your order to meet your exact specifications.

Easy to Use

Receive your parts delivered directly to your door, eliminating the hassle of sourcing, project management, logistics, and shipping.

High Quality

Receive high-quality parts delivered directly to your door, eliminating the hassle of sourcing.