Laser Cutting Service

What is Laser Cutting?

Laser cutting is a manufacturing process that uses a focused laser beam to cut, engrave, or etch materials with high precision. The laser beam melts, burns, or vaporizes the material, depending on the type of laser and material being used. The process is highly accurate, efficient, and can be applied to a wide variety of materials, including metal, plastic, rubber, foam, and wood.

Metal Laser Cutting Service

A metal laser cutting service is a specialized offering that uses advanced laser technology to cut and shape metal materials with high precision and efficiency. These services are commonly provided by manufacturers, fabrication shops, and metalworking companies to meet the needs of industries such as automotive, aerospace, construction, electronics, and more.

Metal Laser Cutting Materials List

- 1075 Spring Steel, annealed

- 1075 Spring Steel, Blue Tempered

- 1095 Spring Steel, annealed

- 1095 Spring Steel, blue tempered

- 4130 chrome-moly steel, annealed

- Aluminum 2024-T3

- Aluminum 5052 H32

- Aluminum 6061 T6

- Aluminum 7075 T6

- Aluminum MIC6

- AR400 Steel, hardened

- AR500 Steel, hardened

- Bearing Bronze 932 M07

- Brass 260

- Brass 353 H02

- Brass 464 H01

- Bronze 220 H02

- Bronze 510 H08 (spring)

- Carbon Fiber

- Copper 101, H00 to H01

- Copper 110, Annealed

- Copper 110, H01

- Copper 110, H02

- Corten A588 (Weathered) Steel

- Hot Rolled Steel 1045

- Hot Rolled Steel A569/ASTM A1011

- Nickel 200, annealed

- Nickel 625, annealed

- Pre-Anodized 6061-T6, Black

- Silicon Bronze 655

- Stainless Steel 17-4 PH, annealed

- Stainless Steel 17-7 shim, hardened

- Stainless Steel 301, spring temper

- Stainless Steel 304

- Stainless Steel 304 shim, hardened

- Stainless Steel 304, #4 brushed

- Stainless Steel 316

- Stainless Steel 410, annealed

- Stainless Steel 430, #3 brushed

- Stainless Steel 440C

- Stainless Steel CPM 154

- Stainless Steel S30V, annealed

- Steel 1008, zinc-galvanized

- Steel 1018

- Steel 4140, hardened

- Steel 80CRV2

- Steel A36

- Steel A36, pickled and oiled

- Steel A366/1008

- Steel A572 Grade 50

- Steel G90, galvanized

- Titanium (Grade 2)

- Titanium 6Al-4V (Grade 5)

- Tool Steel D2, annealed

- Tool Steel O1, annealed

Plastic Laser Cutting Service

A plastic laser cutting service is a specialized offering that uses laser technology to cut, engrave, or etch various types of plastic materials with high precision. This service is often utilized by industries such as electronics, automotive, packaging, medical, and signage, where precision, speed, and minimal material waste are critical.

Plastic Laser Cutting Material List

- ABS, Black

- ABS, White

- Acetal, Black

- Acetal, White

- Acrylic, Clear

- Acrylic, Colored

- Buna-N Rubber, Adhesive-Backed, Black

- Buna-N Rubber, Black

- EPDM

- EVA Foam, Black

- EVA Foam, Blue

- Extra Soft PU Foam, Adhesive Backed, Black

- Extra Soft PU Foam, Black

- Fiberglass

- Flame-Retardant PU Air Filter Pad, Gray

- Flame-Retardant Silicone Foam, Gray

- Garolite G-10 (FR4), Black

- Garolite G-11 (FR5), Green

- Garolite LE (Phenolic), Brown

- HDPE, White

- High Temp Silicone Foam, Adhesive Backed, Red

- High Temp Silicone Rubber, Adhesive-Backed, Red

- High Temp Silicone Rubber, Red

- Nylon 6/6, Black

- Paper Fiber and Buna-N Blend, Gray

- PETG Plastic, Clear

- Polycarbonate, Clear

- Polypropylene, White

- PTFE Gasket Material

- PTFE, White or Black

- PVC, Gray

- UHMW-PE, White

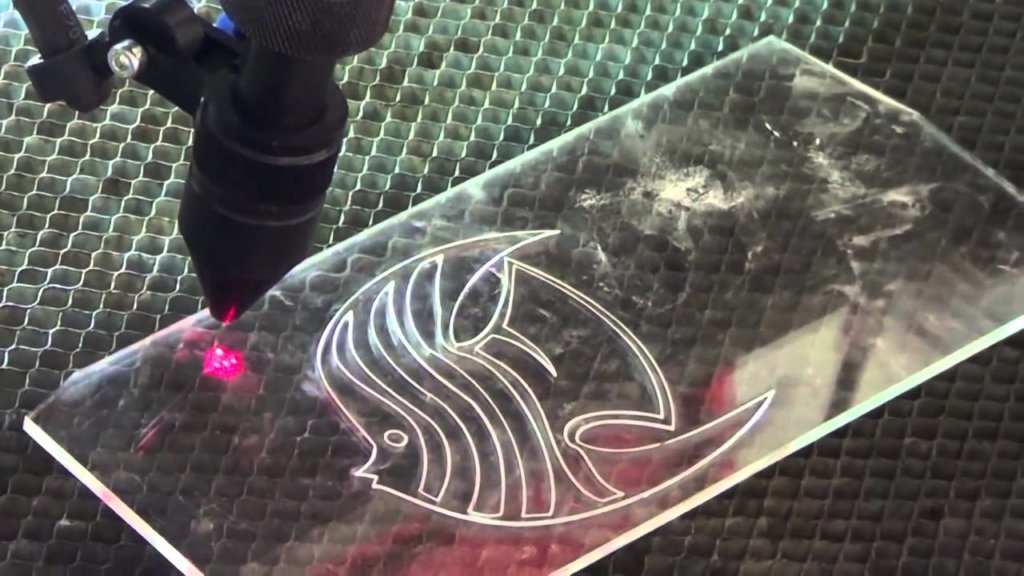

Acrylic Laser Cutting Service

An Acrylic Laser Cutting Service is a specialized service that uses laser technology to precisely cut, engrave, and shape acrylic materials. Acrylic, often referred to as PMMA (Polymethyl Methacrylate), is a versatile, transparent plastic widely used in a variety of applications, including signage, displays, architectural elements, lighting, and artistic designs.

Wood Laser Cutting Service

A Wood Laser Cutting Service utilizes laser technology to precisely cut, engrave, and shape wood materials with high accuracy. This service is widely used in industries such as furniture, signage, interior design, prototyping, and art, due to the versatility of wood as a material and the precision that laser cutting provides.

Types Of Laser Cutters

Laser cutters are machines that use focused laser beams to cut, engrave, or etch various materials with high precision. There are different types of laser cutters based on the technology they use, the materials they work with, and their specific applications. Below are the main types of laser cutters:

CO2 Laser Cutters

- Technology: These lasers use a mixture of carbon dioxide, nitrogen, and hydrogen gases to generate a high-powered beam of light.

- Materials: CO2 lasers are most effective for cutting and engraving non-metal materials such as wood, acrylic, plastics, glass, and fabric. They can also cut some thin metals (such as mild steel and aluminum) with the right setup.

- Applications:

- Ideal for cutting wood, acrylics, rubber, and fabrics.

- Engraving and cutting in signage, arts, and crafts, and packaging.

- Advantages:

- High precision and clean cuts.

- Low cost and versatile.

- Limitations:

- Less efficient for cutting metals compared to fiber lasers.

Fiber Laser Cutters

- Technology: Fiber lasers use a fiber-optic cable doped with rare-earth elements like ytterbium to generate the laser beam. This method produces a highly concentrated beam of light.

- Materials: Fiber lasers are mainly used for cutting metals, including stainless steel, aluminum, brass, copper, and titanium.

- Applications:

- Primarily used in the metalworking industry for cutting sheet metal and engraving on metal surfaces.

- Used for cutting and engraving in the automotive, aerospace, and electronics industries.

YAG Laser Cutters (Neodymium YAG or Nd:YAG)

- Technology: YAG lasers use a neodymium-doped yttrium aluminum garnet crystal to generate a laser beam. These lasers can operate in both pulsed and continuous wave modes.

- Materials: YAG lasers can cut metals, including stainless steel, mild steel, aluminum, and brass. They are also used for certain plastics and ceramics.

- Applications:

- Metal cutting in industries such as manufacturing, automotive, and electronics.

- Engraving or marking on various materials, including metals and plastics.

Laser Cut Metal General Tolerances

| Description | General Tolerance |

|---|---|

|

General Tolerances |

For full details on tolerances offered by Avinyaworks sheet cutting service, including edge to edge tolerance and taper, please consult our manufacturing standards. |

|

Thickness Dimension |

Thickness tolerances are determined by the material blank. |

|

Minimum Recommend Part Size |

1.000″ |

|

Minimum Feature Size |

2X material thickness with a minimum of 0.062″ |

|

Kerf (slit size) |

Approximately 0.020″ |

|

Edge Condition |

Laser cut parts will have a vertical striation on the cut face. |

Advantages of Laser Cutting

High Precision and Accuracy

- Laser cutting offers exceptional precision, allowing for intricate designs, tight tolerances, and sharp edges. The precision is often measured in micrometers, which is significantly better than other cutting methods.

- This makes laser cutting ideal for complex shapes, fine detailing, and customized parts.

Minimal Material Waste

- Laser cutting uses a focused laser beam, which means the width of the cut (kerf) is very narrow. This results in minimal material loss compared to traditional cutting methods that often require additional finishing or produce more waste.

- Additionally, the efficiency of laser cutting is higher, as parts can be tightly packed together during the cutting process, further reducing waste.

No Physical Contact with the Material

- Unlike mechanical cutting methods, laser cutting does not involve direct contact between tools and the material. This means there is no wear on the cutting tool, which reduces tool maintenance and allows for more consistent results over time.

- The lack of physical contact also means there’s no risk of material deformation, scratching, or other damage caused by contact during the cutting process.

Ability to Cut a Wide Range of Materials

- Laser cutting is versatile and can work with a variety of materials, including metals, plastics, wood, acrylic, ceramics, glass, rubber, and textiles.

- It can also handle thin and thick materials efficiently, making it suitable for a variety of industries and applications, such as aerospace, automotive, fashion, and signage.

Clean and Smooth Cuts

- Laser cutting is a fast process, especially for small to medium production runs. The speed of the cutting is dependent on the material and thickness, but in general, laser cutting is faster than traditional methods like sawing, milling, or punching.

- This increased speed can lead to faster turnaround times and higher productivity in manufacturing environments.

High Repeatability and Consistency

- Laser cutting is highly consistent and repeatable, which is especially beneficial for large production runs. Once a design is programmed into the system, it can be reproduced with exact precision for every part.

- This ensures uniformity across all pieces, making it suitable for mass production of identical parts or components.

Why Choose Avinyaworks for Laser Cutting Service?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our quality check includes visual inspection, dimensional verification, functionality testing (if applicable), and a review of surface finish.