Sheet cutting is a critical process in many industries, from manufacturing to construction, where large sheets of materials such as metal, plastic, or wood are cut into smaller, more manageable pieces for various applications. Whether you’re a DIY enthusiast or working in a professional setting, understanding the key techniques and tools for sheet cutting can significantly improve your results.

What is Sheet Cutting?

Sheet cutting involves the precise cutting of flat sheets of material into specific shapes or sizes. This can be done using various methods, including manual cutting, laser cutting, CNC cutting, or shear cutting. Each method has its own set of advantages, depending on the material type, thickness, and the desired end product.

Common Cutting Methods:

Shear Cutting: This is a mechanical process that uses shear force to cut through materials. It’s ideal for cutting thin sheets of metal or plastic with high precision.

Laser Cutting: Laser cutting uses a focused laser beam to cut through materials. It’s perfect for intricate and complex designs with high accuracy, particularly in industries like aerospace and automotive.

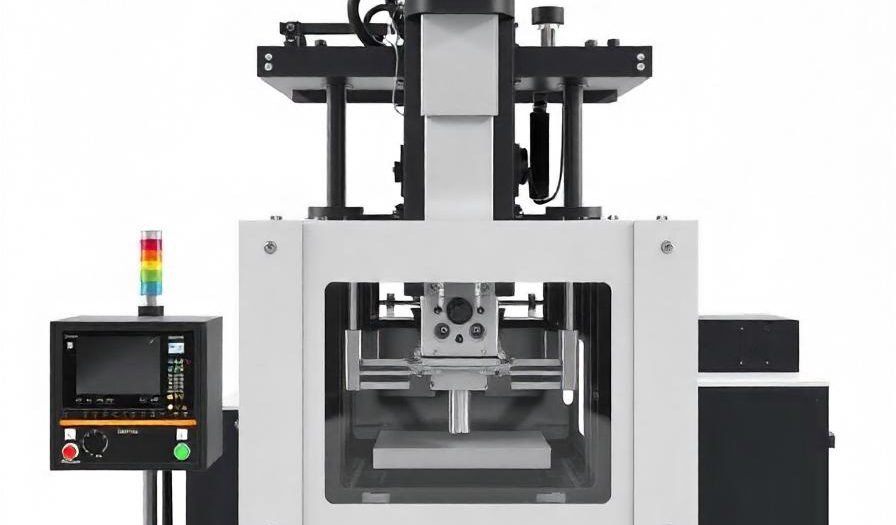

CNC Cutting: Computer Numerical Control (CNC) cutting utilizes automated machines to cut materials with high precision. It allows for consistency and complex designs, making it widely used in manufacturing.

Waterjet Cutting: Using high-pressure water mixed with abrasives, waterjet cutting is effective for cutting through thicker materials like stone, metal, or glass without generating heat.

Choosing the Right Method:

Selecting the best cutting technique depends on factors such as material type, thickness, precision requirements, and the complexity of the design. For example, laser cutting is ideal for precise, intricate patterns, while shear cutting works best for larger, simpler cuts.

Applications of Sheet Cutting:

Sheet cutting is found in a wide range of industries:

Manufacturing: Used to cut parts for machinery, automobiles, and consumer goods.

Construction: Essential for cutting materials like metal sheets or plywood for building and infrastructure projects.

Arts & Crafts: Artists and hobbyists use various sheet cutting techniques for creating designs in paper, metal, or other materials.

Electronics: Used in the production of circuit boards and components.

Tips for Successful Sheet Cutting:

Measure Twice, Cut Once: Always double-check measurements to ensure accuracy before cutting.

Use the Right Tools: Invest in quality cutting tools appropriate for the material you’re working with.

Ensure Proper Safety: Wear safety gear such as gloves, goggles, and hearing protection when cutting sheets, especially when using heavy machinery or cutting metals.

Conclusion:

Sheet cutting may seem simple, but it’s an essential skill that requires the right tools, techniques, and knowledge. Whether you’re crafting a DIY project or working in a professional setting, understanding the different methods and choosing the best approach will ensure clean, precise cuts that meet your project’s needs.

Recent Posts

-

How Much Does CNC Machine Cost17 Jan 2025

How Much Does CNC Machine Cost17 Jan 2025 -

The Art and Science of Sheet Cutting: Precision, Techniques, and Applications15 Jan 2025

The Art and Science of Sheet Cutting: Precision, Techniques, and Applications15 Jan 2025 -

Outsourcing Your CNC Machining Needs In 202213 Jan 2025

Outsourcing Your CNC Machining Needs In 202213 Jan 2025 -

20 Powerful Industries That Benefit From CNC Machining13 Jan 2025

20 Powerful Industries That Benefit From CNC Machining13 Jan 2025 -

Why is Polycarbonate Used in Injection Moulding?13 Jan 2025

Why is Polycarbonate Used in Injection Moulding?13 Jan 2025

Categories

- Blogs

- 3D Printing Articles

- Injection Molding Articles

- Machining Articles

- Sheet Cutting Articles